8-head liquid filling chuck-type double-lock cap production line

1、Improve production efficiency

2、Guarantee product quality

3、Adaptable to various bottle shapes and caps

4、Health and safety

5、Reduce costs

- Overview

- Recommended Products

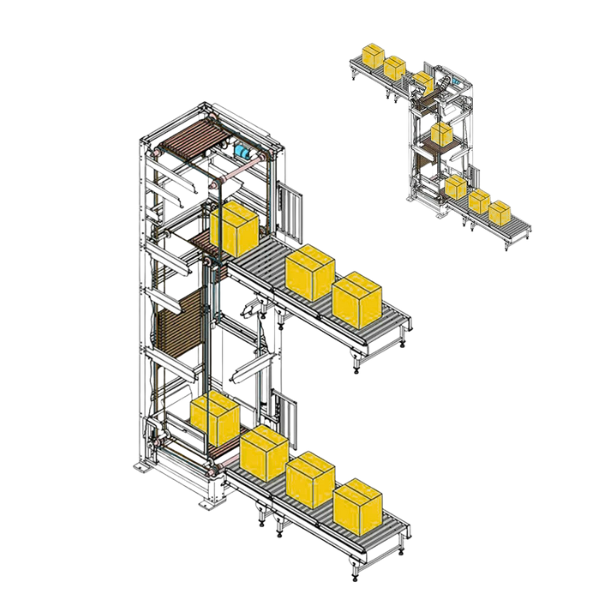

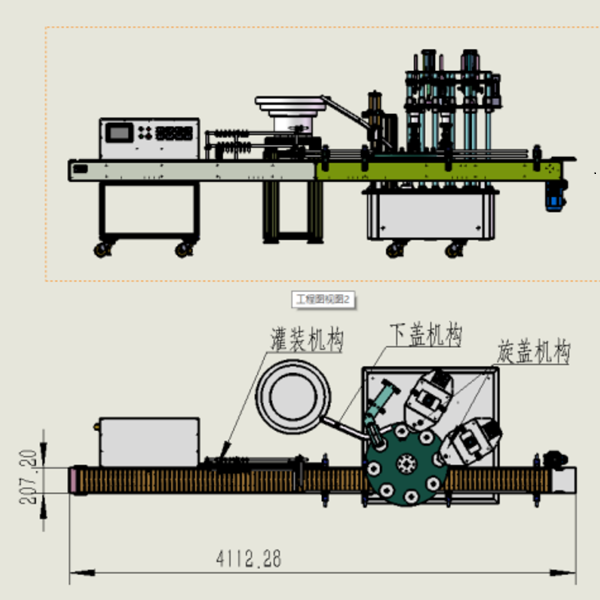

Working Principle

1. Chuck Positioning: Fixes bottles and conveys them to the filling area per preset parameters;

2. Liquid Filling: Bottles connect with filling pumps (gear pump, piston pump, etc. optional) for precise filling by set volume;

3. Double Capping Operation: Bottles are transferred to the capping station, caps are placed by mechanical/pneumatic devices, and tightened by double capping mechanisms for sealing.

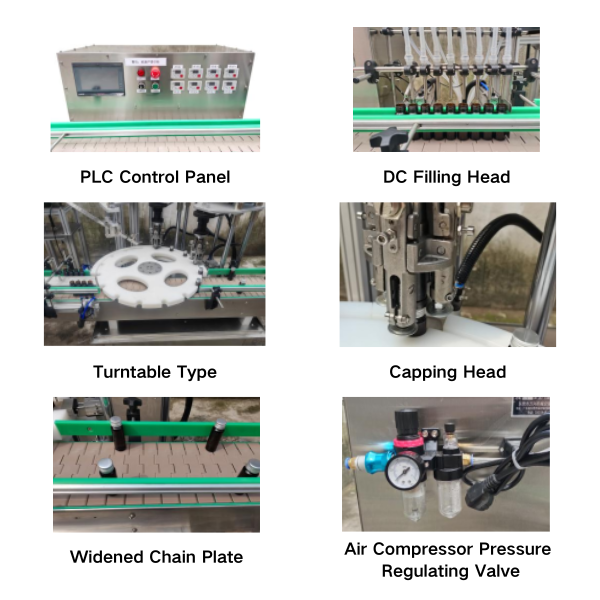

Equipment Composition

1. Bottle Feeding System: Bottle storage rack + conveyor belt for orderly bottle supply;

2. Chuck-type Filling Machine: Core equipment with chuck, turntable, filling pump, etc., realizing positioning, filling and transfer;

3. Cap Sorting & Feeding Device: Electromagnetic vibratory bowl sorts caps, which are conveyed to the capping station via feeding track;

4. Double Capping Machine: Two sets of capping mechanisms (electric/pneumatic/mechanical) for secure sealing;

5. Conveying System: Conveyor belt, chain, etc., connecting equipment for bottle transfer;

6. Electrical Control System: PLC + touch screen for parameter setting, fault alarm and automatic shutdown.

Relevant Parameters

| Filling Error | ±1% |

| Number of Filling Heads | 8 heads (customizable) |

| Filling Speed | Customized according to production capacity |

| Maximum Flow Rate | 5L/head/min (based on water) |

| Capping Speed | 20-25 pcs/min per head |

| Capping Range | Customizable according to customer’s cap sample |

| Number of Capping Heads | 2 heads (customizable) |

| Maximum Suction Lift | 2 meters |

| Power Supply | 220V/50HZ |

| Applicable Air Source | 0.4-0.6MPA |

| Equipment Material | Combination of 304 stainless steel and aluminum alloy |

| Equipment Power | 3000W |

Applicable Scenarios

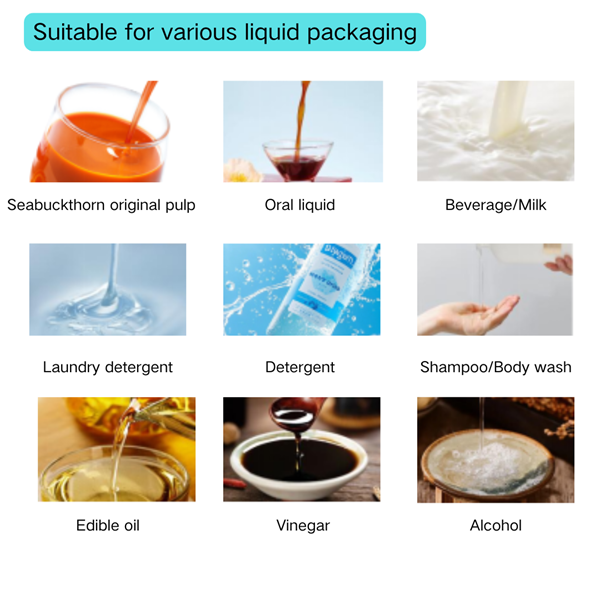

Food & Beverage Industry: Filling and capping of liquid foods (juice, beverage, soy sauce, vinegar, edible oil, etc.).

Pharmaceutical Industry: Filling and packaging of oral liquids, medicines, injections, etc., complying with GMP standards to ensure quality and safety.

Daily Chemical Industry: Filling and capping of daily chemicals (essential oil, perfume, essence water, toner, laundry detergent, cosmetic lotion, etc.).

Chemical Industry: Suitable for filling and packaging of liquid chemicals (glue, coating, ink, solvent, etc.).