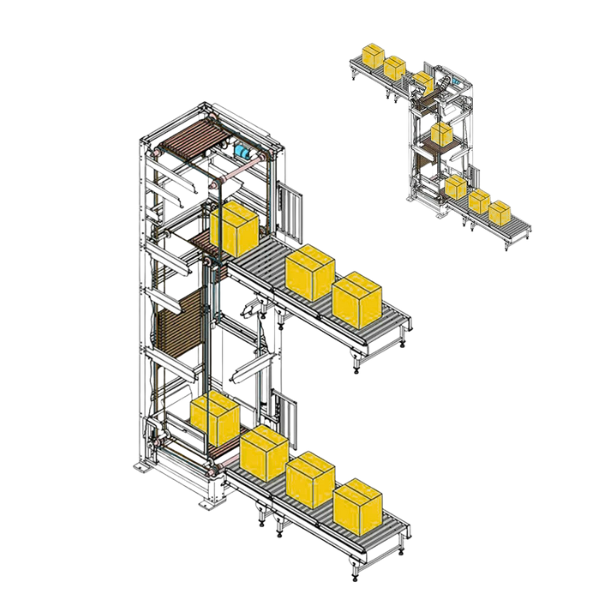

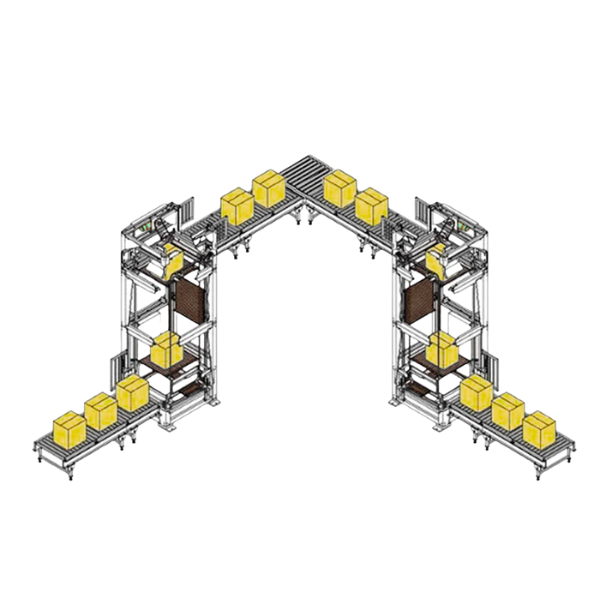

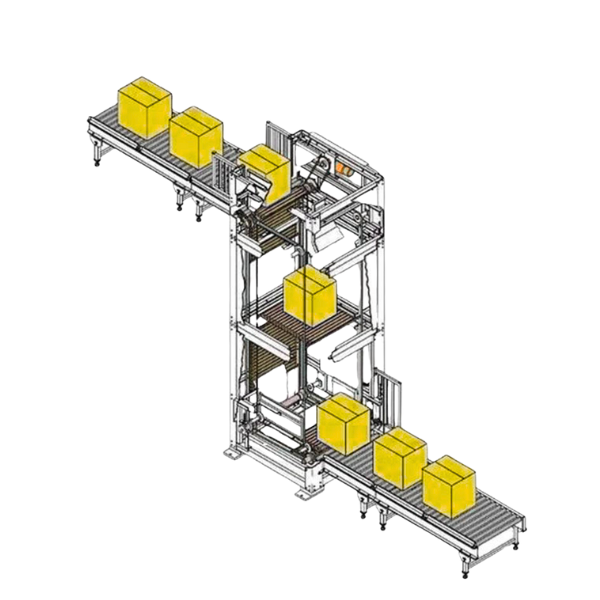

Lifting Table Conveyor

Integrated Lifting & Conveying, Efficient Connection

Precise Speed & Height Control, Stable & Reliable

Flexible & Adaptable, Strong Compatibility

Safe & Easy to Operate, Convenient Maintenance

- Overview

- Recommended Products

Product Details

1. Basic Parameters

Drive Mode: Hydraulic Drive / Electric Drive (Optional)

Lifting Height: 500-3000mm (Customizable)

Table Size: 800×600mm~2000×1200mm (L×W, Customizable)

Conveying Speed: 0.5-3m/s (Adjustable)

Rated Load: 500-3000kg (Optional)

Table Material: Carbon Steel Spray-coated / Stainless Steel (Optional)

Power Supply: AC 220V/380V 50Hz

Operating Noise: ≤65dB

2. Core Structure & Features

Structure: Composed of lifting tabletop, conveying rollers/belt, drive system and load-bearing frame; compact structure, small floor space.

Features: Stable lifting without impact, conveying surface level error ≤2mm; supports manual/automatic control switching for different operation needs; some models with movable casters for flexible movement.

Relevant Attributes

Binding Strap Material: Alloy Steel

Material: Stainless Steel / Carbon Steel

Rotational Speed: Adjustable

Special Feature: Easy to Clean

Color: Customizable

Scenario Details Description

1. Applicable Industries & Scenarios

Logistics & Warehousing

Manufacturing Industry

E-commerce & Express Delivery

Food & Daily Chemicals

2. Operation & Maintenance Points

Operation: Connect power supply, set lifting height and conveying speed via panel, switch manual/automatic mode; place materials stably on tabletop and start equipment to complete lifting and conveying.

Maintenance: Regularly inspect drive system, hydraulic oil/circuit connections; keep tabletop clean to avoid foreign object jamming; do not overload, stay away from corrosive environments to extend equipment service life.