1.5-1.8 Ton Lithium-Ion Forklift

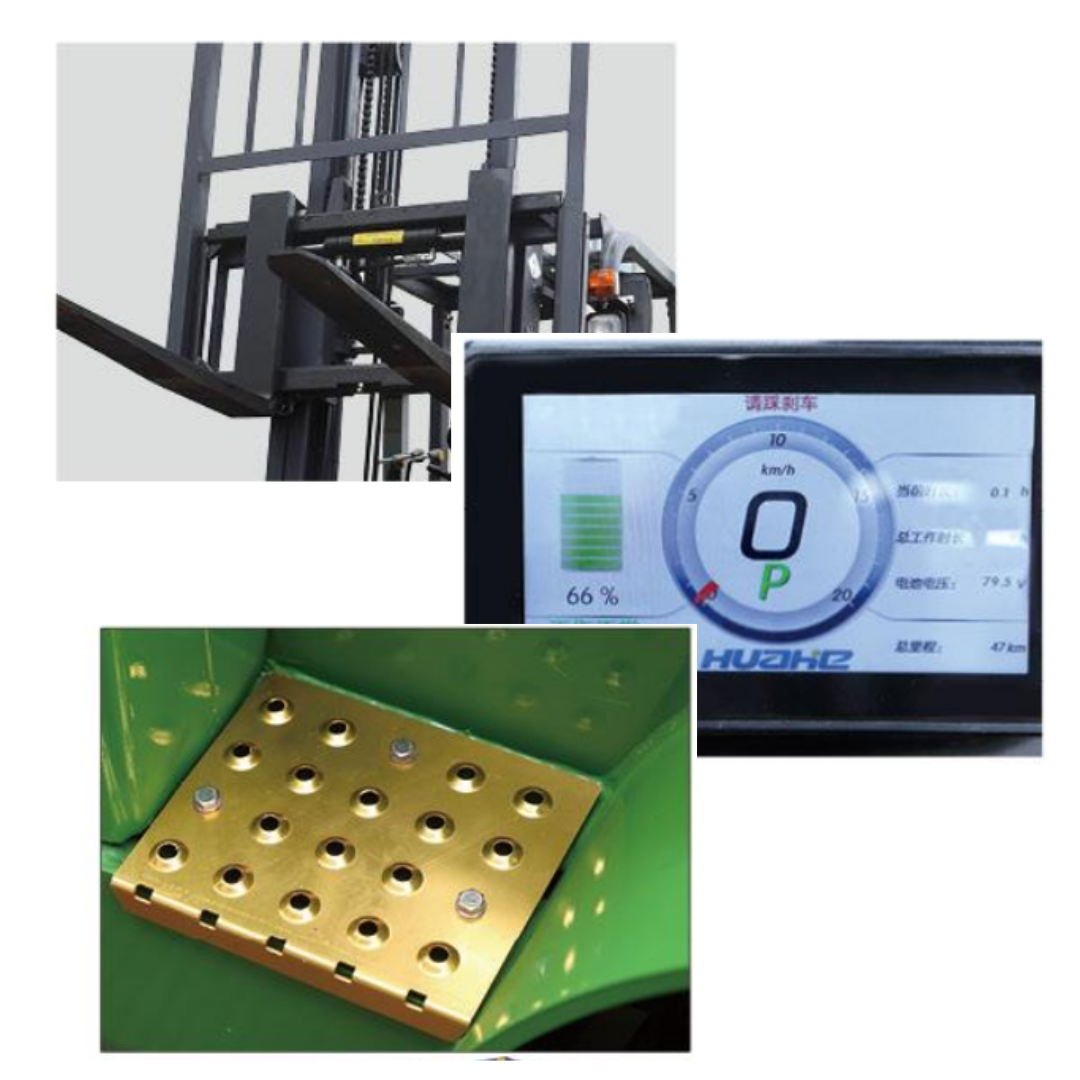

Mast lowering with buffer function: Effectively reduces the impact of loaded cargo during descent, ensuring smooth and safe operation.

Intelligent interface display, convenient and intuitive: Various performance parameters are clearly visible at a glance, and fault codes can also be displayed.

Luxury gold foot pedal, highlighting noble elegance.

Suitable for various ambient temperatures, ranging from -30°C to 60°C.

- Overview

- Recommended Products

Product Details

1.5-1.8T load, 1.6-4.5m lift; 48V Li-ion, 8-12h runtime.

Zero emission, low noise; precise control.

Multiple safety protections; -30~60℃ adaptable.

Works with conveyors/sorting machines; cost-saving.

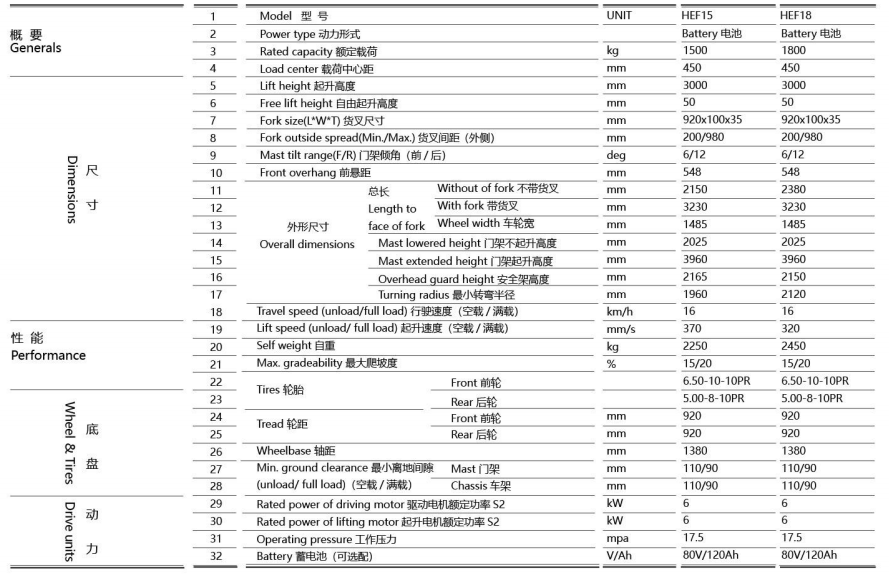

Relevant Parameters

Scenario Details Description

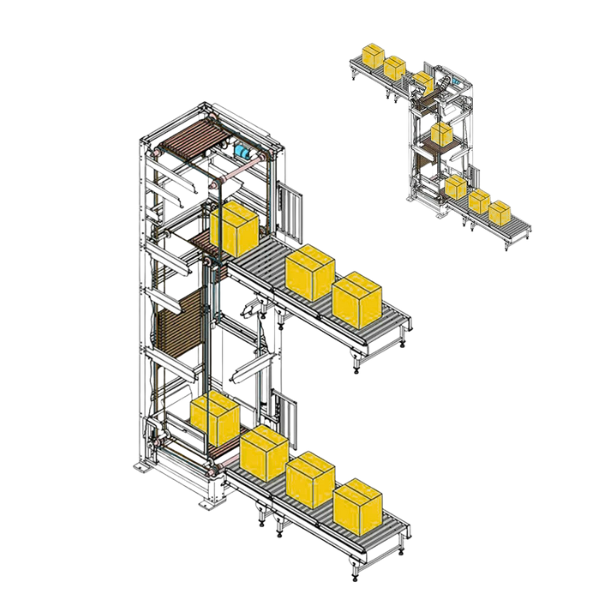

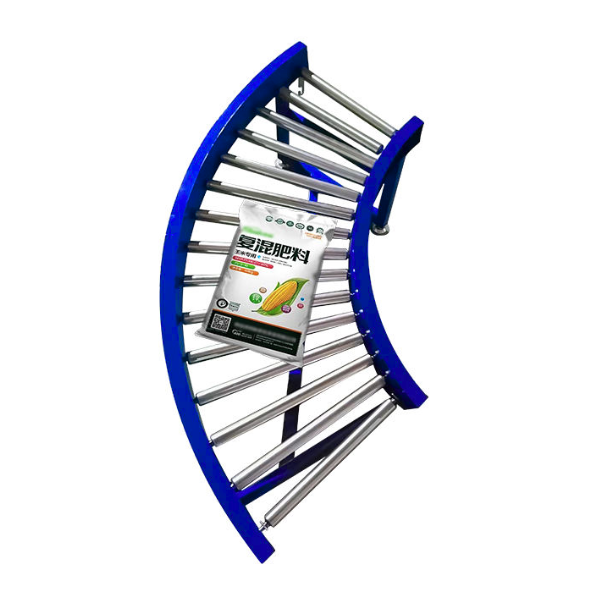

Industrial Conveyor Collaboration: Continuous Workshop Transfer

Application Scenarios: Raw material supply and finished product transfer in auto parts, electronics, building materials and other workshops.

Collaboration Logic: Forklift picks up materials from warehouse, parks accurately at conveyor inlet (height error ≤50mm), returns for replenishment after material transfer; finished products at conveyor outlet are promptly transferred by forklift to avoid congestion.

Core Advantages: Low noise adapts to workshop environment, speed regulation matches conveyor rhythm, efficiency 3-5 times higher than manual handling.

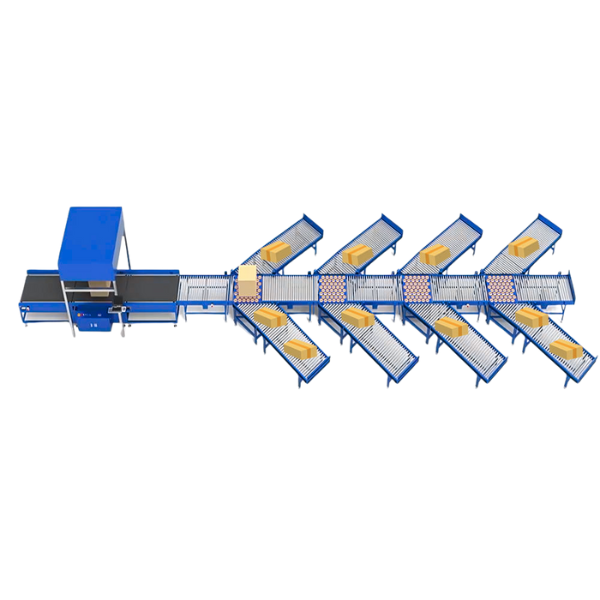

Express Automatic Sorting Machine Collaboration: Warehouse & Distribution Parcel Transfer

Application Scenarios: Inbound parcel supply and sorted parcel transfer at express hubs and e-commerce warehouses.

Collaboration Logic: Inbound stage: 1.5-2T stand-on forklift transfers parcels to sorting machine feeding table, ensuring 2000-3000 pieces/hour processing capacity; post-sorting: forklift transfers parcels from chutes to transport vehicles, 3-5T extended fork model for large parcels.

Core Advantages: Zero-emission for enclosed warehouses, sensitive braking to prevent collisions, 12-hour continuous operation, transfer error rate ≤0.1%.

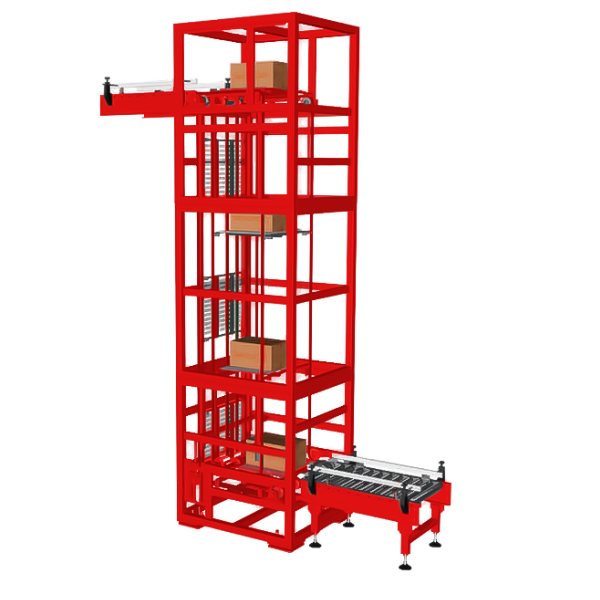

Hybrid Collaboration: Full-Link Connection

Application Scenarios: Large e-commerce logistics parks (e.g., Cainiao Park), connecting warehousing, conveying and sorting links.

Collaboration Logic: Forklift transfers warehouse goods to conveyor → conveyor transports to sorting machine feeding table → post-sorting forklift transfers to transport vehicles, forming closed-loop operation with daily parcel handling capacity over 100,000 pieces.