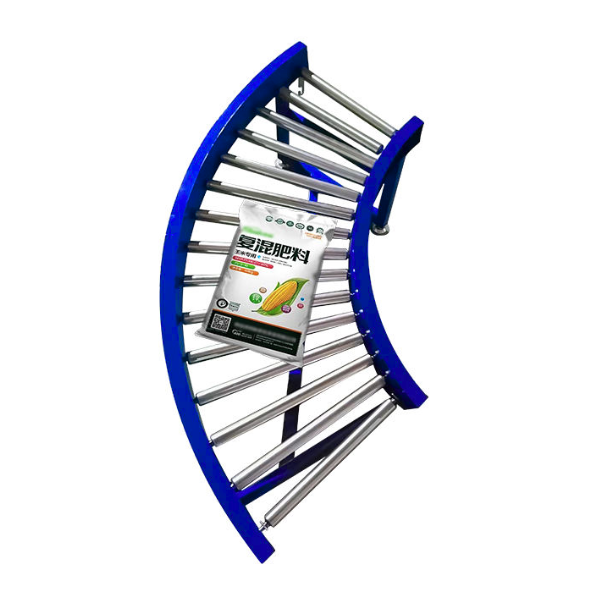

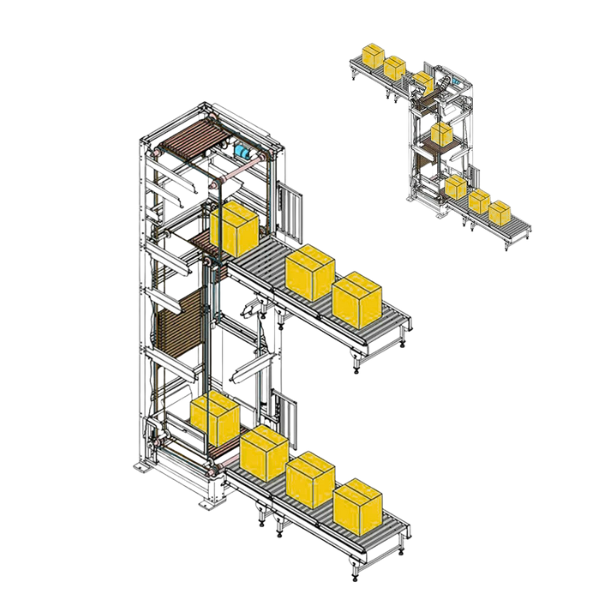

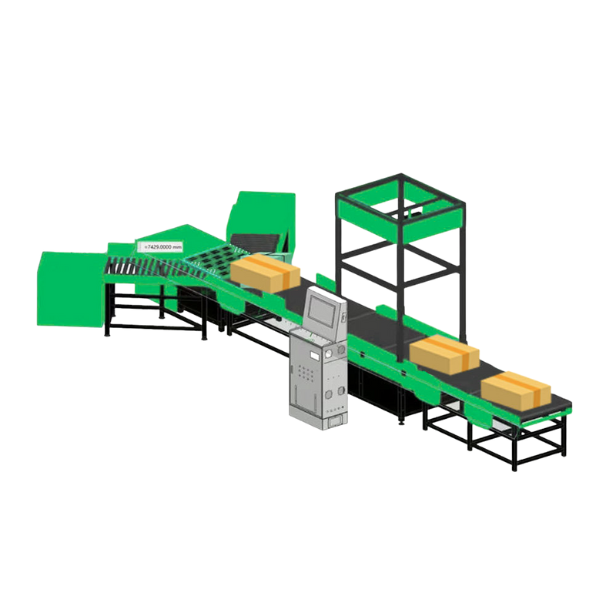

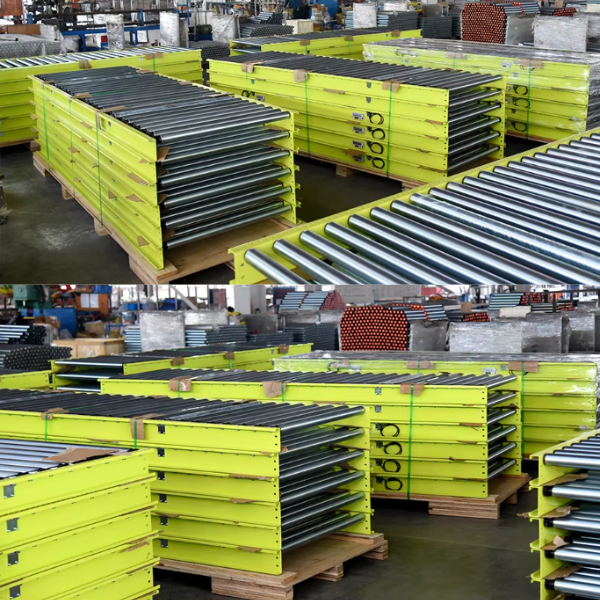

Fixed Powered Roller Conveyor

High conveying efficiency and strong load-bearing capacity

Stable operation and low failure rate

Strong adaptability to automation

Simple structure and convenient maintenance

Flexible compatibility and versatile application scenarios

- Overview

- Recommended Products

Product Details

Customizable Parameters: Speed 0.5-3m/s (frequency conversion), load capacity 50-500kg/m; rollers 38-159mm×500-3000mm (seamless steel pipe/stainless steel), frame Q235 with spray coating/304 stainless steel; motor reducer drive (chain/synchronous belt), protection class IP54/IP65, electric control supporting manual/automatic mode and MES integration.

Core Structure: Rollers (cold-drawn pipe + deep groove ball bearings, multiple surface treatments); Drive (0.75-5.5kW motor + worm gear reducer, efficiency ≥90%, noise ≤65dB, reversible); Frame (steel pipe welding, with adjustable feet/fixed anchors, optional baffles and guide wheels).

Relevant Parameters

| Drive mode | Belt Driven |

| Width | 500/600/800/1000/1200mm |

| Expandable Length / unit | 1000mm/1250mm/1500mm |

| Shorten length / unit | 530mm |

| Roller Dia. | 50mm |

| Pitch Size | 60/80/110mm |

| Central distance | 110/140/160mm |

| Power | 60-90w/m |

| Material of roller | Carbon steel / stainless steel 201/304 as customized |

Scenario Details Description

Fixed-line roller conveyors are widely used in scenarios such as e-commerce logistics (warehouse inbound/outbound, pre-sorting transportation), food and pharmaceutical industries (material transfer in production lines, finished product transportation), automotive manufacturing (workshop parts circulation), home appliance and electronics industries (assembly line transportation), and chemical building materials industry (post-packaging material transfer).

They allow selection of suitable roller materials (galvanized, rubber-coated, stainless steel) and load-bearing specifications based on material types (e.g., cartons, pallets, metal parts, food containers), support horizontal or small-inclination (≤15°) transportation, and can be linked with automated equipment (sorting machines, sensors).

Usage Precautions

Place materials in the center to avoid uneven force on the rollers; small-sized materials must be paired with pallets or belts to prevent falling. For humid/dusty environments, select models with IP65 protection rating; for high-temperature environments, use high-temperature resistant bearings.

In daily use, regularly check bearing lubrication, fasten frame bolts, and clean foreign objects on the rollers to ensure stable operation of the equipment.