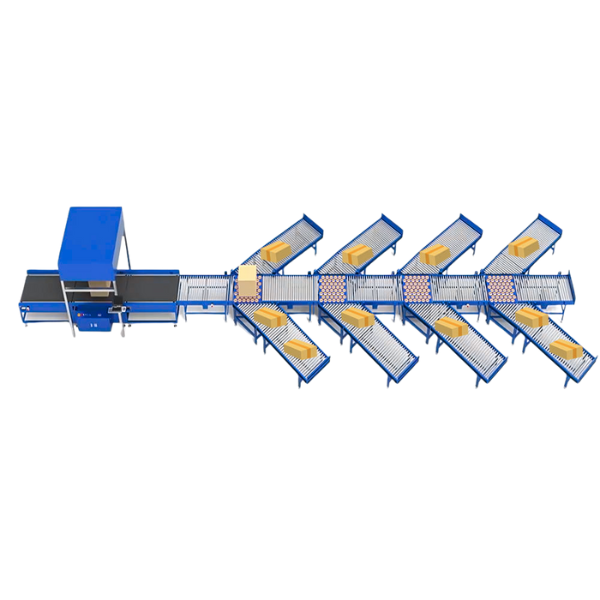

Automatic Sorting Belt Conveyor

1. High Efficiency & Large Volume

2. High Precision & Low Error

3. Time-Saving & Labor-Saving

4. Flexible Adaptation

5. Stable & Easy to Manage

6. Customization on Demand

Customization is available for sorting speed, number of sorting channels, identification technologies (e.g., barcode/RFID/vision), conveying materials (food-grade/industrial-grade), and protective functions (dustproof/waterproof) based on requirements, enabling adaptation to the special operating environments and sorting standards of different industries.

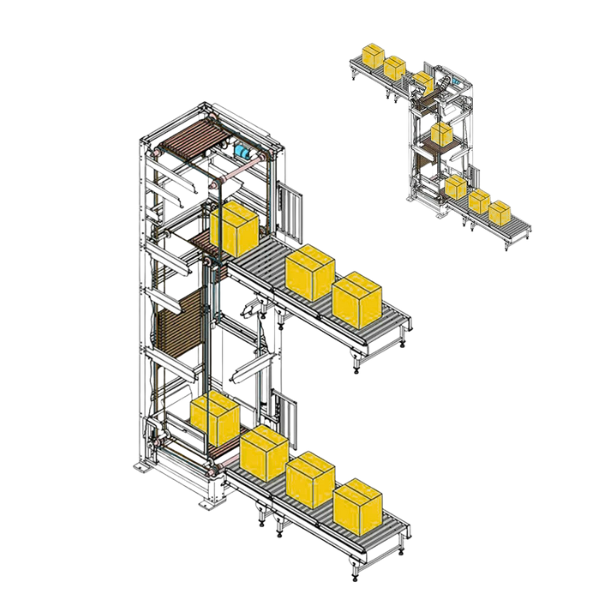

- Overview

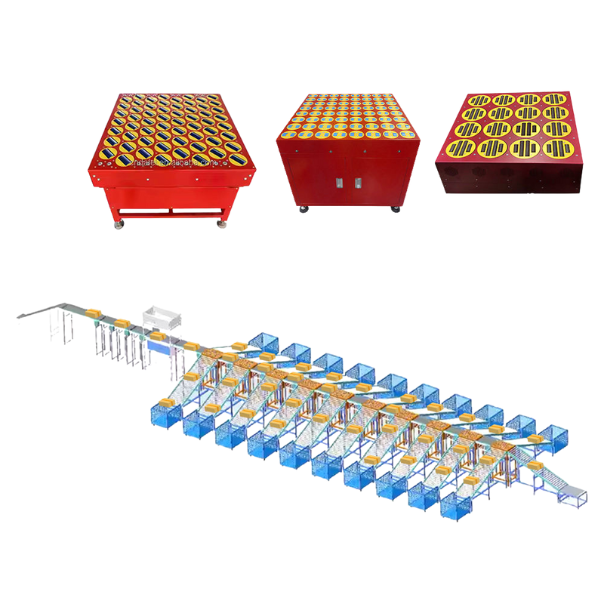

- Recommended Products

Product Details

1、High sorting efficiency with large processing capacity

2、High degree of automation, reducing manual intervention

3、Accurate sorting precision, lowering mis-sorting rate

4、Modular design for easy expansion and maintenance

5、Adaptable to multi-category items, enabling flexible sorting

6、Stable operation with low failure rate

7、Traceable data, facilitating management

Relevant Parameters

| Package size | L80-500mm,W100-500mm,H8-500mm |

| Package weight | 20g-20Kg |

| Weighing accuracy | <5kg±10g,5kg-20kg±20g |

| Weighing and sorting speed | 35000PCs/H |

| Human machine interface | Keyboard, mouse |

| Display screen | 21inch LCD |

| External communications | Ethernet, USB |

| Power supply | AC220V/50HZ |

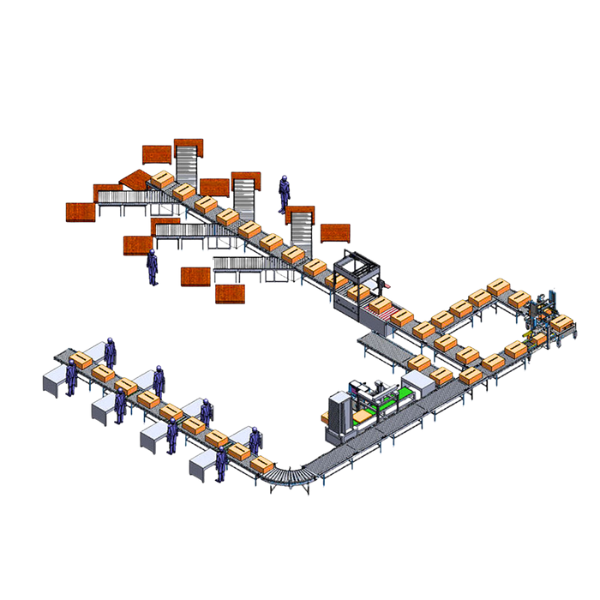

Scenario Details Description

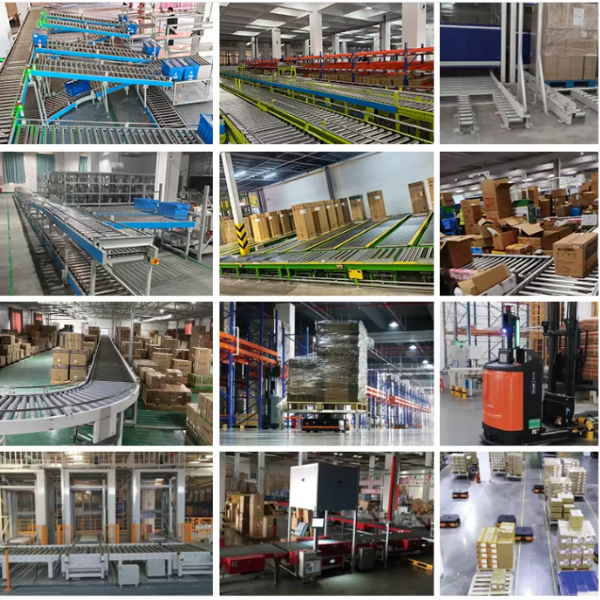

It is widely used in scenarios such as e-commerce warehouses (order sorting), express transfer stations (regional distribution), food/pharmaceutical workshops (product classification), manufacturing industry (parts sorting), and supermarket distribution centers (commodity allocation). It is especially suitable for sorting operations with high throughput, multiple categories, and high precision requirements.