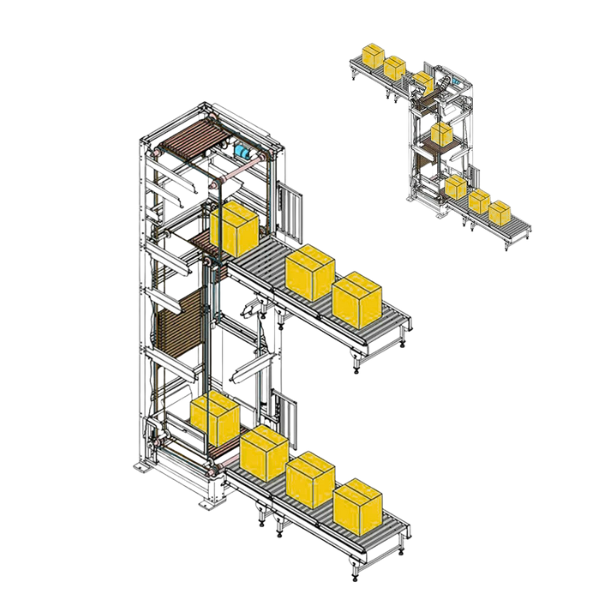

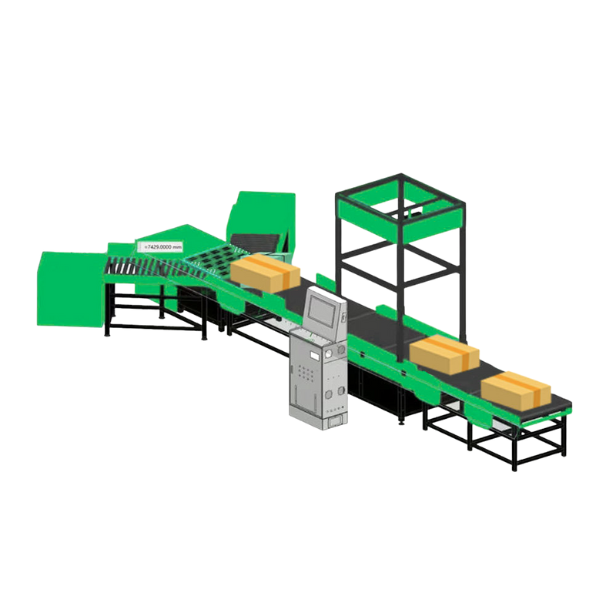

Adjustable telescopic manual roller belt conveyor system

Flexible Telescoping

Easy Operation

Flexible Conveying

Portable & Practical

- Overview

- Recommended Products

Features and advantages

Flexible Telescoping: Manually adjustable telescopic length, adapting to different working distances without site modification.

Easy Operation: Manual control of conveying direction and on/off, no complex debugging, quick to master.

Flexible Conveying: Roller + belt combination ensures stable conveying, reducing wear of light cargo.

Portable & Practical: Lightweight structure, easy to move, suitable for temporary connection or small-batch operations.

Product Overview

The adjustable telescopic manual roller belt conveyor system is a manually operated conveying equipment focusing on flexible adaptation. Combining the advantages of roller and belt conveying, it realizes stable transfer of light cargo. It supports manual adjustment of telescopic length, allowing quick adjustment of conveying distance according to operation needs, suitable for warehouses, stores and other venues. The manual control mode is simple to operate without professional training, and the lightweight structure is easy to move, making it suitable for temporary connection, small-batch sorting and other scenarios. Equipped with wear-resistant belt and high-quality rollers, the equipment has strong durability and low operation and maintenance costs, widely used in short-distance conveying, cargo connection and other scenarios to improve operational flexibility.

Relevant Parameters

| Telescopic stroke | 1-5m (manual adjustment) |

| Conveying speed | 0.3-1m/s (manual control rhythm) |

| Applicable cargo weight | ≤30kg |

| Cargo size range | 15×10×3mm - 800×600×400mm |

| Belt width | 300/400/500mm (optional) |

| Machine material | Carbon steel with powder coating / aluminum alloy (optional) |

| Roller diameter | 40/50mm (optional) |

| Equipment weight | 30-80kg (depending on length) |

| Operating temperature | -10-45℃ |

Applicable Scenarios

Warehousing Logistics: Temporary connection and short-distance transfer of inbound/outbound goods.

Retail Stores: Commodity replenishment conveying for supermarkets and convenience stores, adapting to different shelf distances.

Small Logistics Points: Small-batch sorting and short-distance conveying of express parcels and small commodities.

Manufacturing Industry: Manual inter-process transfer of light components, flexibly adapting to workstation layout.