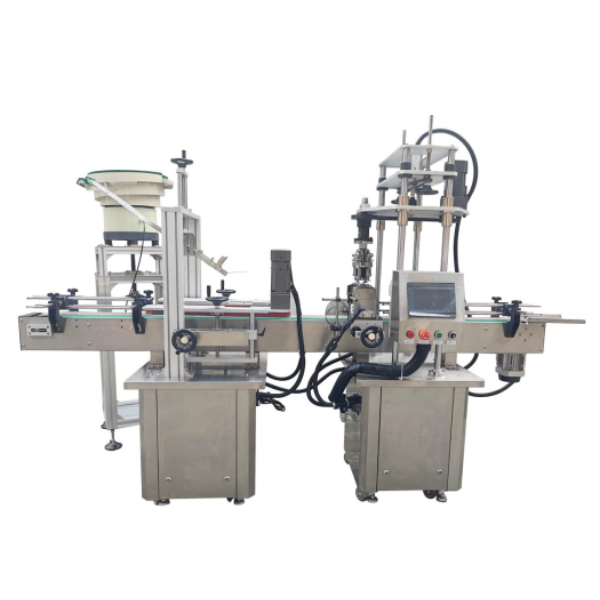

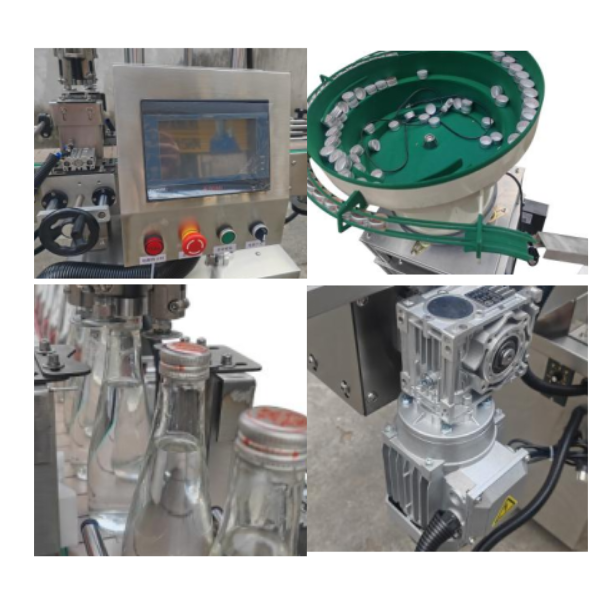

Fully automatic cap locking machine

High Automation

High Precision & Stability

High Speed

Strong Adaptability

High Safety

Traceability

- Overview

- Recommended Products

Features and advantages

High Automation: Auto-feeds and locks caps, boosting efficiency and reducing labor costs.

High Precision & Stability: Accurate control of position/force, ensuring firm sealing and low scrap rate.

High Speed: Adapts to different capacities; high-speed models handle tens to hundreds of bottles per minute.

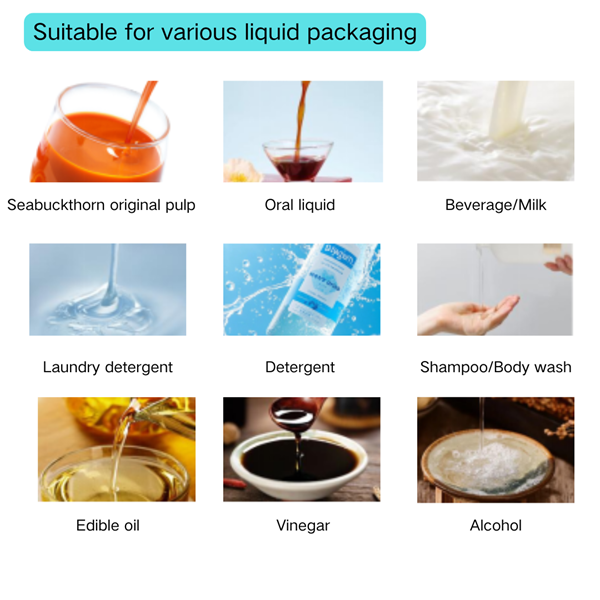

Strong Adaptability: Compatible with various bottle/cap specs via tooling replacement or parameter adjustment.

High Safety: Equipped with photoelectric sensors, emergency stops, protective doors, etc.

Traceability: Some models record production volume, capping torque and other data for traceability.

Product Overview

Working Principle

Capping Feeding: Caps stored in hoppers are sorted and conveyed via vibratory bowls/lifting belts to above bottle mouths; some devices have visual inspection for precise feeding.

Capping Locking: After bottles reach the station, the capping mechanism places caps on mouths, then secures them via screwing, pressing or crimping for tight sealing.

Relevant Parameters

| Capping Error | ±1% |

| Capping Head Quantity | Single Head (Customizable) |

| Capping Speed | 20–25 pcs/min |

| Capping Range | Customized per Customer's Sample Cap |

| Vibratory Bowl Cap Sorting | For One Cap Specification Only |

| Equipment Power Supply | 220V/50HZ |

| Applicable Air Pressure | 0.4–0.6MPA |

| Equipment Material | Combination of 201 Stainless Steel and Aluminum Alloy |

| Equipment Power | 600W |

Applicable Scenarios

Food & Beverage: Capping for beverage, mineral water, can, sauce bottles, etc.

Daily Chemical: Capping for shampoo, skincare, cosmetic bottles, etc.

Pharmaceutical: Capping for medicine, oral liquid, vial bottles (compliant with GMP).

Chemical: Capping for chemical raw materials, reagents, lubricating oil, etc.