Oil stain remover filling machine, capping machine, screw capping machine, aluminum foil sealing machine

Improved Efficiency

Consistent Quality

Labor Savings

Enhanced Packaging Image

- Overview

- Recommended Products

Features and advantages

Improved Efficiency: Full automation from filling to sealing reduces manual steps, enabling continuous, high-speed packaging to cut costs.

Consistent Quality: Precise filling, stable capping, and reliable sealing ensure uniform packaging quality, reducing leaks and spoilage to enhance product qualification rates and competitiveness.

Labor Savings: Reduces labor dependence and intensity, minimizes human errors, and lowers labor costs.

Enhanced Packaging Image: Neat, standardized packaging improves product appearance and brand value.

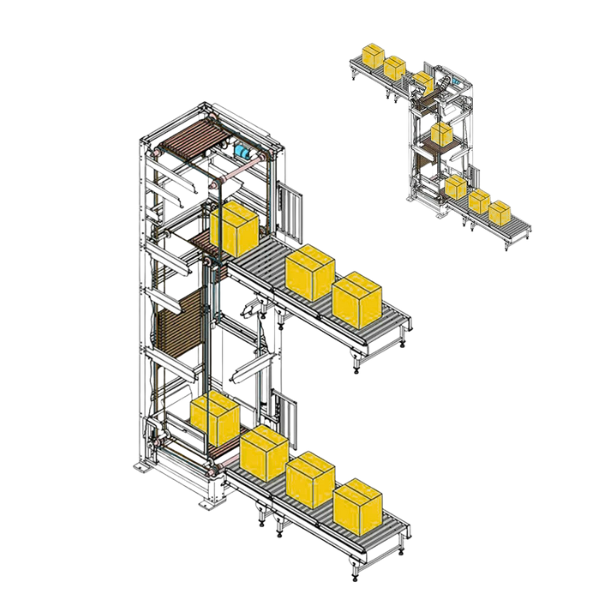

Product Overview

Basic Composition

Filling Machine: Quantitatively fills liquids, pastes, etc., into packaging containers (plastic bottles, glass bottles, etc.). Common types: volumetric, weighing, and atmospheric pressure filling machines.

Capping Machine: Accurately places caps on filled containers for subsequent capping. Equipped with automatic cap feeding systems for fast, stable cap supply and precise positioning via mechanical arms or other devices.

Screw Capping Machine: Tightens caps placed by the capping machine to ensure good sealing. Types include handheld, semi-automatic, and fully automatic (commonly used in production lines with adjustable torque control for optimal tightness).

Aluminum Foil Sealing Machine: Uses electromagnetic induction or heat pressing to seal aluminum foil on container mouths, enhancing leak-proofing, freshness retention, and protection against contamination.

Working Principle

Filling Machine: - Volumetric type: Measures materials via fixed-volume chambers. - Weighing type: Achieves quantitative filling through load cells. - Atmospheric pressure type: Relies on gravity for filling low-viscosity, foam-free liquids.

Capping Machine: Organizes and conveys caps via vibratory bowls to the capping position, then places them precisely on bottle mouths using mechanical or pneumatic devices.

Screw Capping Machine: Driven by motors or pneumatic motors, generates rotational torque to tighten caps. Equipped with torque control systems for adjustable tightness based on cap and packaging requirements.

Aluminum Foil Sealing Machine: - Electromagnetic induction type: Induces current in aluminum foil via alternating magnetic fields to melt sealing materials. - Heat pressing type: Seals foil by heating and pressing with thermal devices.

Relevant Parameters

| Filling error | ±1% |

| Number of filling heads | 6 heads (customizable) |

| Filling speed | 1000-1500 bottles/hour |

| Filling range | 100-1000mL |

| Capping range | 20-60mm |

| Maximum suction lift | 2 meters |

| Equipment power supply | 220V/50Hz |

| Applicable air source | 0.4-0.6MPa |

| Equipment material | 304 stainless steel and aluminum combination |

| Equipment power | 1000W |

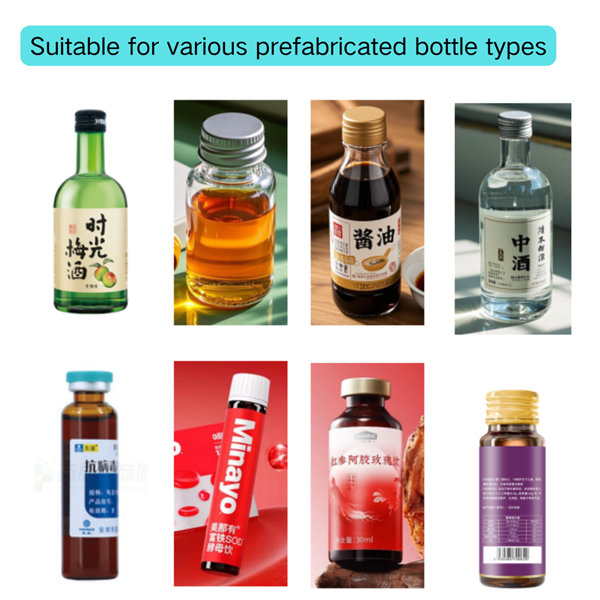

Applicable Scenarios

Food & Beverage: Bottled water, juices, beverages, sauces, edible oils, etc.

Daily Chemicals: Shampoos, body washes, laundry detergents, dish soaps, cosmetics, etc.

Pharmaceutical: Oral liquids, eye drops, medical disinfectants, pharmaceuticals, etc.

Chemical: Liquid chemical raw materials, coatings, adhesives, solvents, etc.