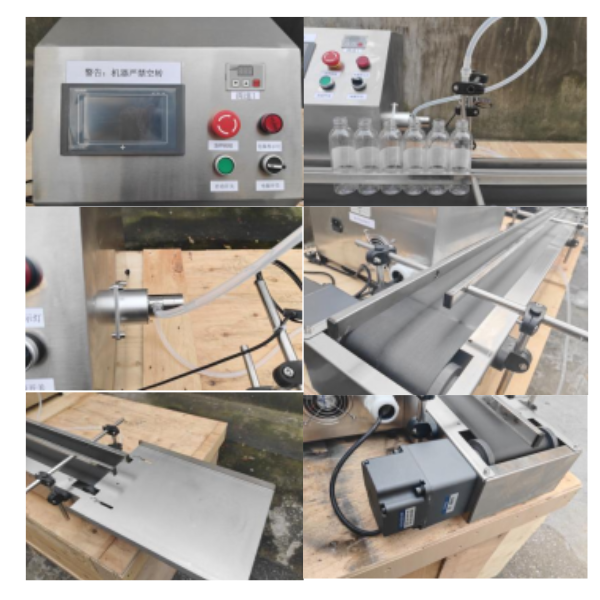

Single-head benchtop magnetic pump filling machine

Compact Size

Easy Operation

High-Precision Filling

Hygienic & Safe

Wide Applicability

- Overview

- Recommended Products

Features and advantages

Compact Size: Bench-top and space-saving design, suitable for laboratories, small workshops and low-output scenarios.

Easy Operation: Equipped with an intuitive control panel (buttons/touchscreen) for convenient parameter setting; no complex training required.

High-Precision Filling: Magnetic pump ensures high conveying accuracy, precise control of flow and filling volume with minimal error, meeting high-precision requirements.

Hygienic & Safe: Liquid-contacting parts are made of compliant materials (stainless steel, engineering plastics), corrosion-resistant, easy to clean, and prevent material contamination.

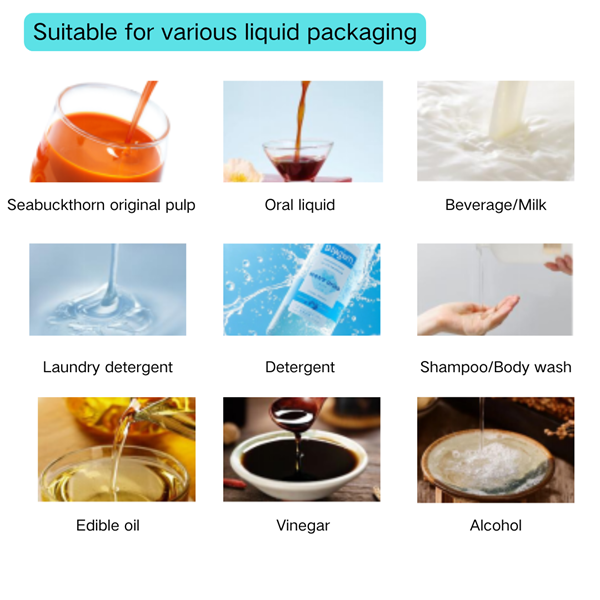

Wide Applicability: Compatible with low to medium-high viscosity liquids (water, alcohol, syrup, lubricating oil, etc.); adaptable to diverse filling needs via parameter adjustment and accessory

Product Overview

The single-head bench-top magnetic pump filling machine conveys and fills liquid via a magnetic pump. Composed of pump body, magnetic actuator (magnetic cylinder), motor and control system, the magnetic pump works as follows: the motor drives the outer magnetic rotor to rotate; its magnetic field penetrates the isolation sleeve to drive the inner magnetic rotor to rotate synchronously, which in turn drives the impeller to suck liquid from the inlet and discharge it from the outlet. Set the filling volume through the control system; the magnetic pump stops running when the preset volume is reached, completing a single filling cycle.

Relevant Parameters

| Filling Error | ±1% |

| Filling Head | Single head (customizable) |

| Filling Speed | 40–50 pcs/min |

| Max Flow Rate (water-based) | 5L/min |

| Filling Range | 2ML–100ML (customizable for volumes over 100ML) |

| Max Suction Lift | 2m |

| Power Supply | 220V/50HZ |

| Applicable Air Source | No air source required (pure electric liquid filling) |

| Equipment Material | 201 Stainless Steel & Aluminum Alloy Combination |

| Equipment Power | 300W |

Applicable Scenarios

Food Industry: Filling of small-batch liquid foods such as condiments (soy sauce, vinegar, oyster sauce), beverages (fruit juice, milk), and edible oil.

Pharmaceutical Industry: Filling of oral liquids, pharmaceuticals, and reagents in laboratories and small pharmaceutical enterprises, meeting strict requirements for precision and hygiene.

Daily Chemical Industry: Filling of skincare products (serum, lotion), cosmetics (nail polish, perfume), and detergents (hand wash, dish soap), etc.

Chemical Industry: Filling of small-dose liquid chemical products such as chemical reagents, ink, and adhesives.