Small stand-up pouch rotary filling machine

Compact Design

Easy Operation

High Filling Precision

Wide Applicability

Hygienic & Safe

- Overview

- Recommended Products

Features and advantages

Compact Design: Small footprint, ideal for space-constrained environments (small enterprises, stores, labs) with flexible placement.

Easy Operation: Intuitive interface; staff can master operation quickly after simple training. Parameters (filling volume/speed, capping torque) are adjustable via touchscreen/buttons, reducing labor intensity.

High Filling Precision: Equipped with high-accuracy metering systems for adjustable, splash-free, leak-proof filling, ensuring consistent volume across all pouches.

Wide Applicability: Compatible with various stand-up pouches (sizes, materials, shapes) and suitable for filling liquids/pastes (beverages, sauces, cosmetics, pharmaceuticals).

Hygienic & Safe: Material-contacting parts and body are mostly made of stainless steel, meeting food/pharmaceutical hygiene standards. Easy to clean and disinfect, preventing material contamination.

Product Overview

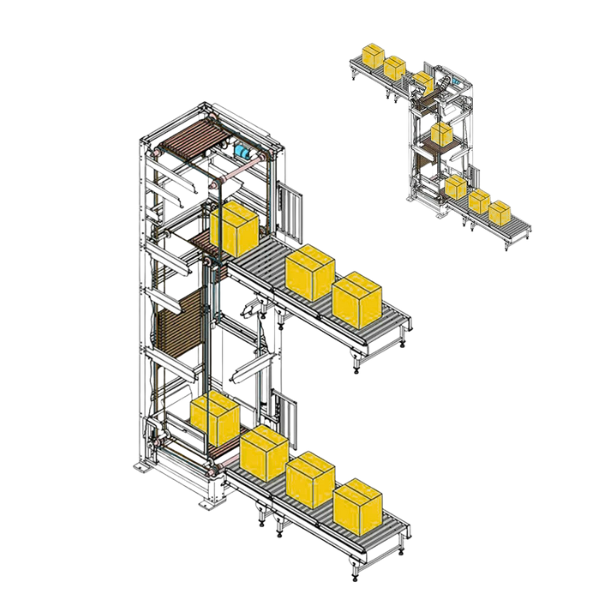

Bag Feeding: Stand-up pouches are automatically hung on turntable stations via a feeding mechanism (e.g., advanced German rodless design) for stable, precise positioning.

Filling: After pouches are positioned, filling systems (plunger pumps/peristaltic pumps, selected by material type) dispense materials. Some systems support nitrogen/gas flushing; integrated metering devices ensure accurate volume control.

Capping: Caps are sorted by an organizing mechanism, guided to pouch openings, and tightened by a capping system for reliable sealing.

Bag Discharging: Filled and capped pouches are removed from the turntable by an unloading mechanism and conveyed to the next process.

Structural Composition

Turntable System: Core component mounted at the center, with evenly distributed pouch-hanging forks to fix and rotate pouches through sequential stations.

Filling System: Includes a storage tank (for holding materials), metering device (precision volume control), and filling nozzles (accurate material injection).

Cap Feeding & Capping System: Cap feeder delivers caps to the capping position; capping unit (mechanical/pneumatic) tightens caps. Some models feature automatic slip functionality for optimal tightness.

Control System: Coordinates all components, supporting parameter setting, operation mode selection, fault diagnosis, and alarm. Operated via touchscreen or control panel for easy monitoring.

Relevant Parameters

| Filling error | ±1% |

| Number of filling heads | Single head (customizable) |

| Filling speed | 100-600 bags/hour (subject to actual filling based on liquid concentration) |

| Filling range | 30-3000ml (sample-based customization available) |

| Capping range | 20-30mm (rubber head size selectable by cap dimension) |

| Maximum suction lift | 2 meters |

| Equipment power supply | 220V/50Hz |

| Applicable air source | 0.4-0.6MPa |

| Equipment material | Combination of 304 stainless steel and aluminum |

| Equipment power | 1600W |

| Equipment dimensions | 0.90m × 1.1m × 1.65m (L × W × H) |

| Equipment weight | 600kg |

Applicable Scenarios

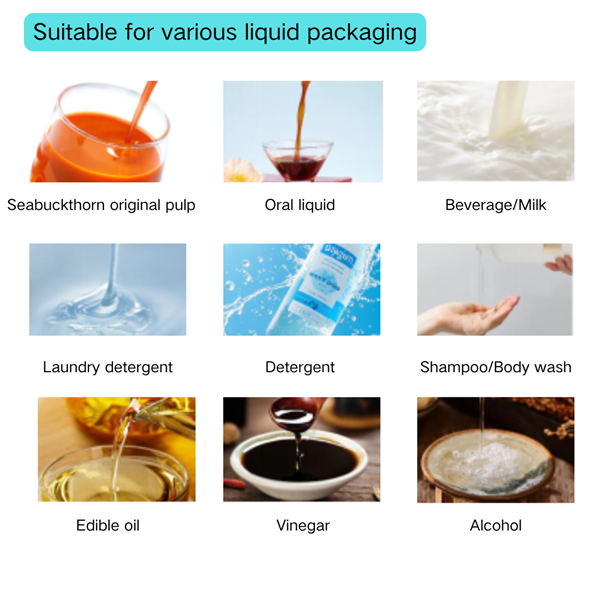

Food & Beverage: Juices, milk, soybean milk, yogurt, sauces, condiments, etc. Stand-up pouch packaging offers portability and excellent shelf display.

Daily Chemicals: Shampoos, body washes, laundry detergents, skin lotions, creams, etc., accommodating diverse packaging specifications.

Pharmaceutical: Oral liquids, syrups, ointments, etc. Precise filling and sealing ensure drug quality and stability, complying with strict pharmaceutical industry requirements.