Stand-up pouch double-head cabinet filling machine

Dual-Head Design

Cabinet Structure

High Automation

Easy Operation

Easy Cleaning & Maintenance

- Overview

- Recommended Products

Features and advantages

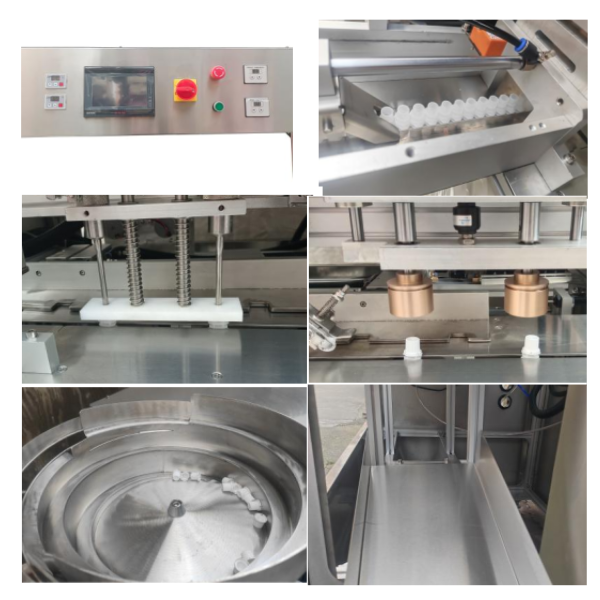

Dual-Head Design: Two filling heads work simultaneously, significantly improving efficiency, suitable for medium output requirements.

Cabinet Structure: Compact, stable and space-saving, easy for workshop layout and linkage with other equipment.

High Automation: Supports automatic bag feeding, opening, filling and sealing; some can be expanded with labeling and coding functions, reducing labor and stabilizing quality.

Easy Operation: Human-machine interface + touchscreen for convenient setting of filling volume, speed, sealing temperature and other parameters.

Easy Cleaning & Maintenance: Material-contacting parts are detachable, complying with hygiene standards, reducing maintenance costs and downtime.

Product Overview

Working Principle

Material Conveying: Materials are temporarily stored in a hopper, then delivered to filling heads via gear pumps, plunger pumps or other transfer pumps.

Measuring Control: Precise quantitative filling is achieved through flow meters (volume measurement) or load cells (weight measurement).

Filling Operation: After the stand-up pouch is in place, the filling head inserts into the pouch mouth for feeding; some equipment has vacuum suction function to prevent dripping.

Relevant Parameters

| Filling Error | ±1% |

| Filling Head Quantity | Double Heads (Customizable) |

| Filling Speed | 1000 bags/hour |

| Filling Range | 30–500 (Unified Bayonet Size) |

| Capping Range | 20–30MM (Optional) |

| Maximum Suction Lift | 2 Meters |

| Equipment Power Supply | 220V/50HZ |

| Applicable Air Pressure | 0.4–0.6MPA |

| Equipment Material | Combination of 304 Stainless Steel and Aluminum Alloy |

| Equipment Power | 2000W |

| Equipment Dimensions | 1.75×1.65×1.73 (L×W×H) |

| Equipment Weight | 1000KG |

Applicable Scenarios

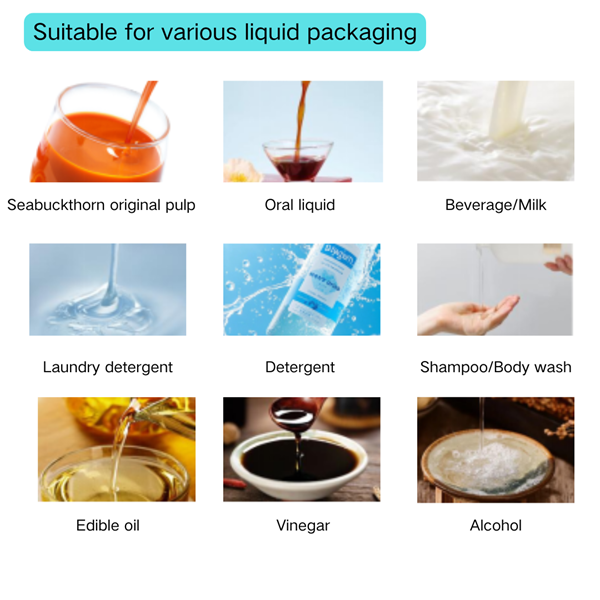

Food Industry: Filling of liquid foods such as fruit juice, milk, sauces and honey, meeting hygiene and precision requirements.

Daily Chemical Industry: Packaging of daily chemical products like shampoo, laundry detergent and hand wash, adapting to different product characteristics.

Pharmaceutical Industry: Filling of liquid medicines such as oral liquids and syrups, complying with hygiene standards and high-precision requirements.

Other Industries: Suitable for stand-up pouch packaging of liquids with different viscosities, such as pesticides, lubricating oil and cleaning agents.