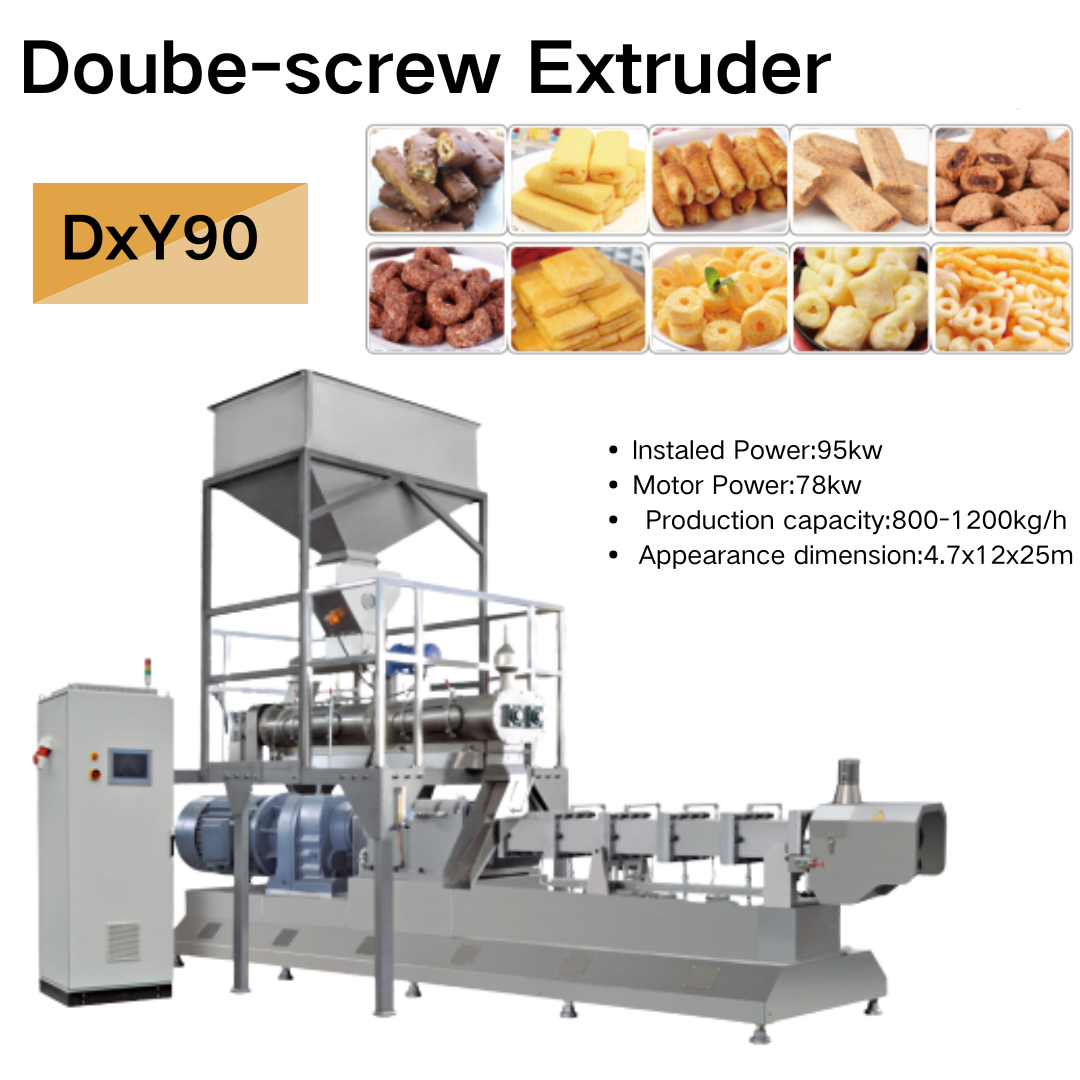

Puffed food processing machine

Integrated Processing

High Efficiency & Energy Saving

Multi-Functional Adaptability

Easy Operation

Safe & Hygienic

- Overview

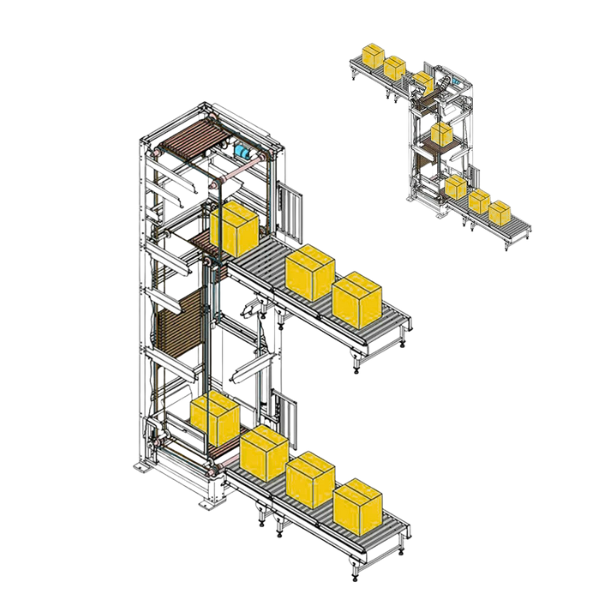

- Recommended Products

Features and advantages

Integrated Processing: Combines raw material mixing, extrusion puffing, molding and flavoring in one, with a compact and efficient process.

High Efficiency & Energy Saving: Adopts high-temperature and high-pressure instant puffing technology, low energy consumption, high output, and shortened processing cycle.

Multi-Functional Adaptability: Can produce French fries, rice cakes, puffed grains and other products; change molds to adjust shapes and specifications.

Easy Operation: PLC control system with intuitive adjustable parameters, high automation, reducing manual dependence.

Safe & Hygienic: Food-contacting parts are made of 304 stainless steel, complying with food hygiene standards, easy to clean and maintain.

Product Overview

This puffed food processing machine is an efficient integrated device suitable for puffing processing of grains, potatoes and other raw materials. It puffs and molds raw materials through high-temperature and high-pressure extrusion technology, and is equipped with replaceable molds and flavoring systems to quickly produce puffed foods of various shapes and flavors. The machine adopts PLC intelligent control, which can accurately adjust temperature, pressure, speed and other parameters to ensure crispy taste and uniform specifications of products. The fuselage is made of safe and environmentally friendly materials, with a structural design convenient for cleaning, balancing production efficiency and food hygiene, and adapting to the mass production needs of small and medium-sized food factories and processing workshops.

Relevant Parameters

| Applicable Raw Materials | Corn, rice, potato starch, grain flour, etc. |

| Production Capacity | 50–200kg/h (depending on model) |

| Puffing Temperature | 120–200℃ (adjustable) |

| Motor Power | 15–37kW |

| Working Voltage | 380V/50HZ |

| Mold Specifications | Customizable (round, strip, special shape, etc.) |

| Fuselage Material | 304 Stainless Steel |

| Control Method | PLC Intelligent Control |

Applicable Scenarios

Small & Medium-Sized Food Factories: Mass production of puffed snacks, breakfast cereals and other products, adapting to market-oriented mass production needs.

Processing Workshops: Small-batch customized production, flexibly adjusting product flavors and shapes to meet local market demands.

Entrepreneurship Projects: Low investment and high output, suitable for food processing entrepreneurship, quickly building production lines.

Food R&D: Suitable for new product R&D scenarios, enabling rapid parameter debugging and testing of puffing effects of different raw material formulas.