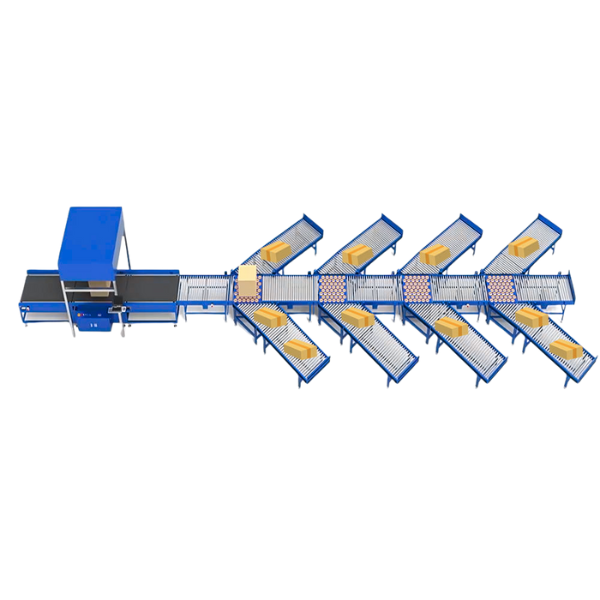

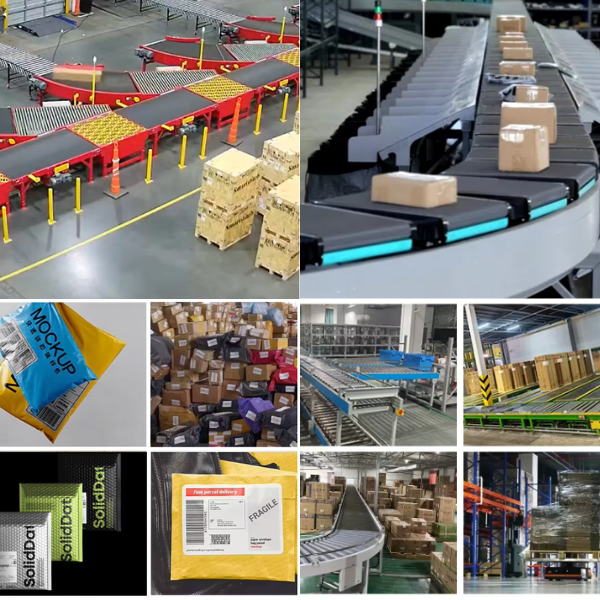

Modular sorting roller conveyor

Modular Design

Efficient Sorting

Flexible Adaptability

Easy Installation & Maintenance

- Overview

- Recommended Products

Features and advantages

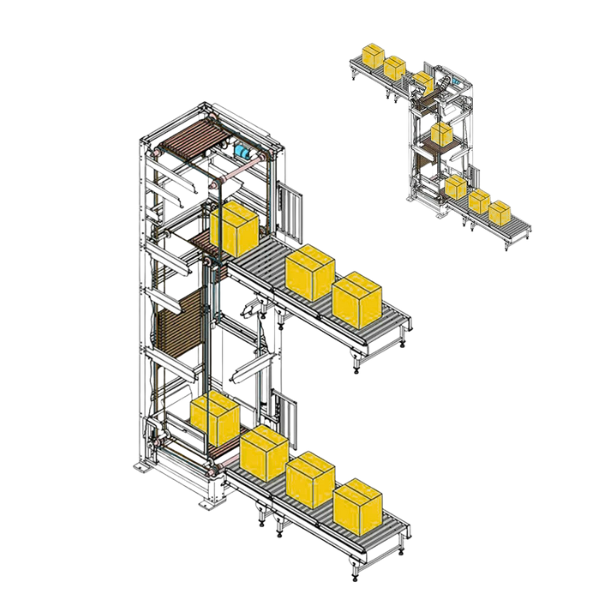

Modular Design: Standardized components enable quick assembly and expansion, adapting to diverse site layouts.

Efficient Sorting: Stable roller transmission ensures high sorting speed while minimizing cargo damage.

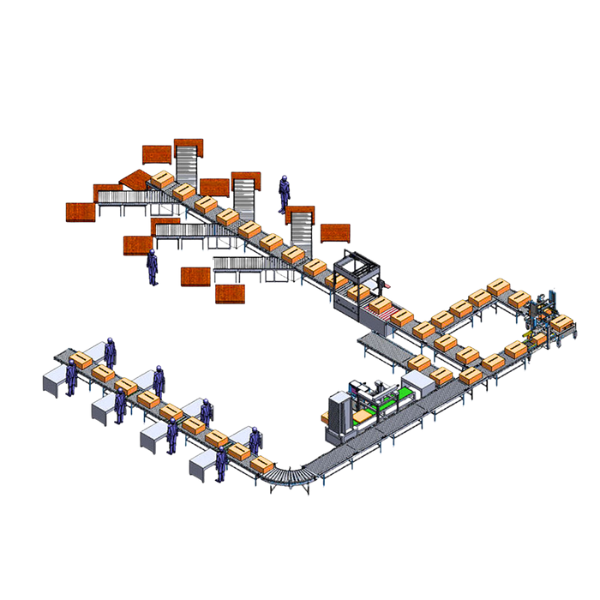

Flexible Adaptability: Compatible with various cargo types (cartons, parcels, turnover boxes, etc.) and integrable with sorting mechanisms.

Easy Installation & Maintenance: Compact structure allows convenient assembly/disassembly, reducing operation and maintenance costs.

Product Overview

The modular sorting roller conveyor is a logistics conveying equipment based on standardized modules. It achieves stable cargo transportation and precise sorting through roller rotation. With a modular splicing design, it can be flexibly combined according to site size and conveying routes, supporting capacity expansion or layout adjustment without complex modifications. Equipped with high-quality rollers and a reliable transmission system, the equipment features low noise and strong load-bearing capacity, suitable for goods of different weights (e.g., cartons, parcels, component turnover boxes). It can be used independently or linked with DWS systems, sorting robotic arms and other equipment, widely applied in logistics sorting, warehousing circulation and other scenarios to enhance conveying and sorting efficiency.

Relevant Parameters

| Roller diameter | 50/60/76mm (optional) |

| Conveying speed | 0.5-2m/s (adjustable) |

| Rated load capacity | 50-300kg/m² |

| Module length | 0.5-3m (standard modules, spliceable) |

| Machine material | 304 stainless steel / carbon steel with powder coating (optional) |

| Power supply | 220V/380V (optional) |

| Power | 0.37-1.5kW (varies by length) |

| Operating temperature | -10-45℃ |

Applicable Scenarios

Logistics Sorting Centers: Sorting, conveying and transshipment of express parcels and e-commerce orders.

Warehousing Logistics: Automatic conveying for raw material inbound and finished product outbound.

Manufacturing Industry: Inter-process transfer and sorting of production line components and finished products.

Food & Pharmaceutical Industry: Compliant with hygiene standards, suitable for clean conveying of packaged food and medicines.