As the logistics industry transitions toward automation and intelligence, manual sorting suffers from low efficiency and high error rates. Traditional conveyors, which only transport in one direction, cannot meet complex needs. Therefore, we have introduced automatic sorting machines and analyze their core value from four perspectives:

1. Reason for Launch: Solving Industry Pain Points

The traditional "manual + conveyor" model faces bottlenecks in efficiency, cost, and accuracy:

E-commerce and other industries have driven a surge in sorting volume, making the traditional model difficult to adapt to the "high-volume, multi-category" demands;

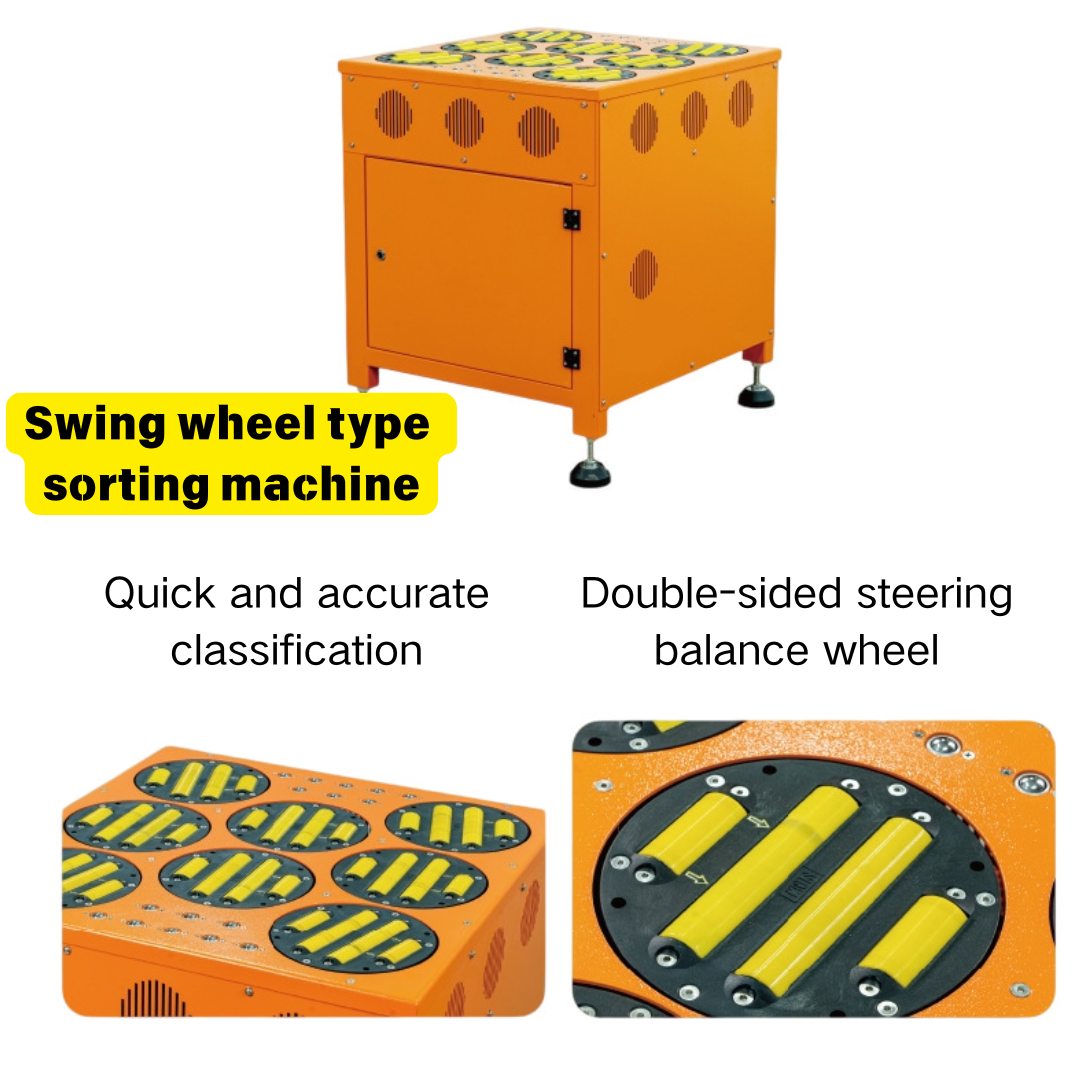

Manual sorting has a high error rate and process gaps. Automatic sorting machines fill this functional gap with their integrated "conveying + identification + sorting" capabilities.

II. Core Advantages: Breakthroughs in Four Dimensions

High Efficiency: Circular track + independent sorting units, 24/7 continuous operation, far exceeding manual efficiency;

Precise Accuracy: High-definition code scanning + intelligent recognition, integrated with the warehousing system, extremely low error rates;

Cost Reduction: Reduced number of sorters, "soft touch" design reduces cargo loss;

Flexibility: Adaptable to a variety of cargo sizes, with quick switching of sorting rules in the backend.

III. Differences from Traditional Conveyors

| Comparison Dimension | Automatic Sorting Machine | Traditional Conveyor |

| Core Function | Conveying + Identification + Sorting + Data Recording + Alarm | One-way conveying only; no sorting or identification function |

| Workflow | Fully automated: scanning, sorting, and data uploading | Manual scanning and sorting required; process is cumbersome |

| Efficiency & Accuracy | High efficiency, low mis-sorting rate | Relies on manual labor; low efficiency, high mis-sorting rate |

| Labor & Data | Minimal monitoring; automatic recording and tracing | Multiple workers for sorting; manual statistics are time-consuming and error-prone |

| Applicable Scenarios | High-volume, multi-category, high-precision scenarios | Single category, fixed-path conveying |

In short, the automatic sorting machine is a comprehensive upgrade of the "mobility + identification + sorting" chain.

IV. Customized Service: Adapting to Demand

Hardware: Customize size and structure based on site, cargo characteristics, and environment.

Software: Customize sorting rules based on business logic and integrate with existing systems.

Service: Flexible installation, tiered training, and efficient after-sales service.

Summary

Automatic sorting machines replace traditional models with intelligent systems, addressing industry pain points and combining efficiency and precision. Customized services can be adapted to different scenarios, helping to reduce costs, improve efficiency, and enhance quality in the sorting process.

Hot News

Hot News