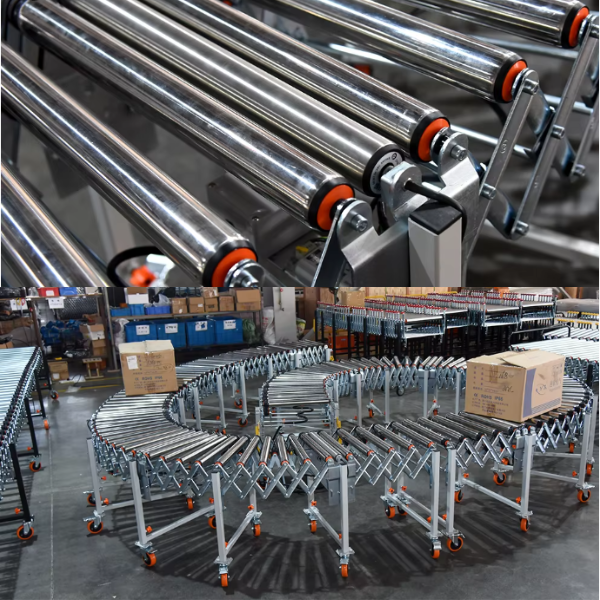

Heavy-duty motorized packaging roller conveyor

Flexible length adjustment, adapting to dynamic conveying distances

Roller conveying, low friction to protect materials

Automatic conveying saves labor and improves efficiency

Durable materials, simple maintenance and low failure rate

Movable, easy to connect with other equipment

- Overview

- Recommended Products

Features and advantages

Flexible length adjustment, adapting to dynamic conveying distances

Roller conveying, low friction to protect materials

Automatic conveying saves labor and improves efficiency

Durable materials, simple maintenance and low failure rate

Movable, easy to connect with other equipment

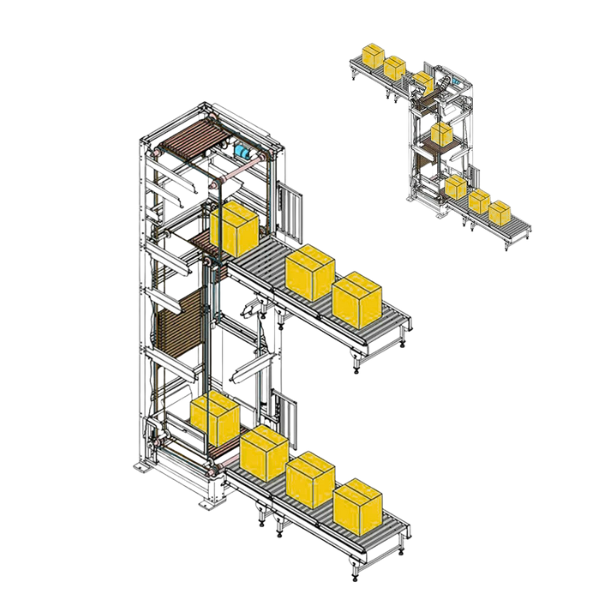

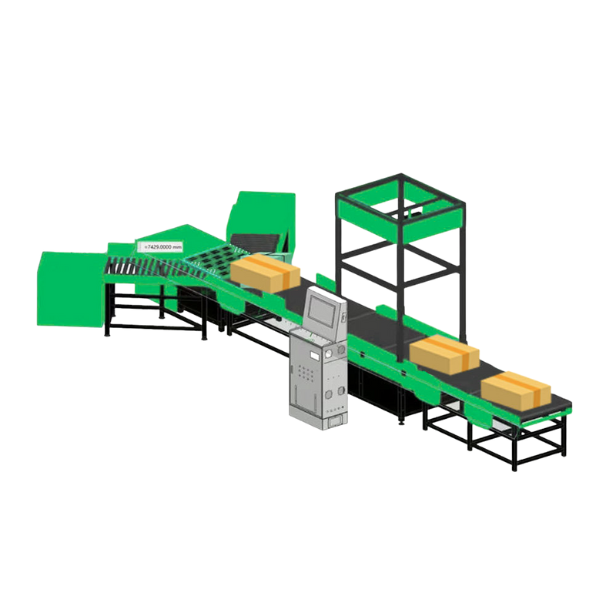

Product Overview

The telescopic roller conveyor has a regular telescopic length of 3-15 meters (customizable up to 20m+), with a variable-frequency adjustable conveying speed of 0.5-1.5m/s. It is equipped with carbon steel/stainless steel rollers (diameter 50-89mm) and has a load-bearing capacity of 50-500kg/m (heavy-duty models customizable up to 1000kg/m+). Driven by electric rollers or geared motors (mute ≤65dB), it supports manual/PLC control (compatible with automated systems). Its structure includes roller brackets (anti-slip optional), telescopic guides (gear rack/chain drive), and motor reducers (some support manual telescoping when powered off). Optional accessories include universal wheels, guardrails, and photoelectric sensors, making it suitable for multiple scenarios.

Relevant Parameters

| Drive mode | Belt Driven |

| Width | 500/600/800/1000/1200mm |

| Expandable Length / unit | 1000mm / 1250mm / 1500mm |

| shorten length / unit | 530mm |

| Roller Dia. | 50mm |

| Pitch Size | 60/80/110mm |

| Central distance | 110/140/160mm |

| Power | 60-90w/m |

| Material of roller | Carbon steel / stainless steel 201/304 as customized |

Applicable Scenarios

1、Warehousing & Logistics: Connect trucks with warehouses/sorting tables, adjust length to fit different vehicle types, transfer materials quickly, and reduce loading/unloading time.

2、Manufacturing: Link production lines of different processes, movable to adapt to flexible production, avoid material accumulation, and improve production line efficiency.

3、Supermarkets/Retail: Used for backstage replenishment and cargo loading/unloading; dedicated materials can be selected for cold chain scenarios to protect fresh goods and reduce manual exposure to low temperatures.

4、Ports/Terminals: Connect containers with yards/vehicles; choose heavy-duty models to adapt to heavy-weight materials and reduce handling risks.