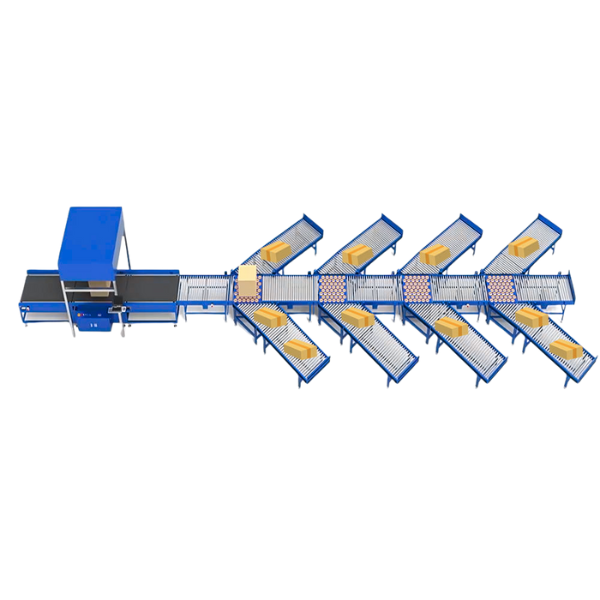

Balance Wheel Sorter

Dual Advantages of Flexible & Heavy-Duty, Benchmark for Damage-Free Sorting

Multi-Dimensional Precision Adaptation, Full-Category Compatibility

Efficient, Low-Consumption Operation & Maintenance, Strong Cost Controllability

Intelligent Integration & Flexibility, Wide Deployment Scenarios

Extreme Environment Adaptation, Stable Operation Globally

- Overview

- Recommended Products

Core Product Advantages

Dual Advantages of Flexible & Heavy-Duty, Benchmark for Damage-Free Sorting: Adopting polyurethane-coated balance wheels and adaptive pressure control technology, the sorting impact force is ≤5N, reducing the damage rate to below 0.01%, enabling safe handling of fragile items and precision instruments. Driven by dual servo motors in coordination, a single module can carry up to 80kg, easily handling large boxes of 1.5m in length and 65kg in weight, with a balance wheel offset of <0.5mm and a sorting success rate of 99.98%.

Multi-Dimensional Precision Adaptation, Full-Category Compatibility: Equipped with a laser vision calibration system and AI contour recognition algorithm, the recognition accuracy for irregular items and reflective surface packaging reaches 99.95%, supporting goods weighing 0.1-80kg and measuring 90×90×10mm to 1500×1000×1000mm. Stepless adjustable sorting angle from 0-90°, capable of single and double-sided operation, suitable for multi-material goods such as cartons, soft packages, woven bags, and metal boxes.

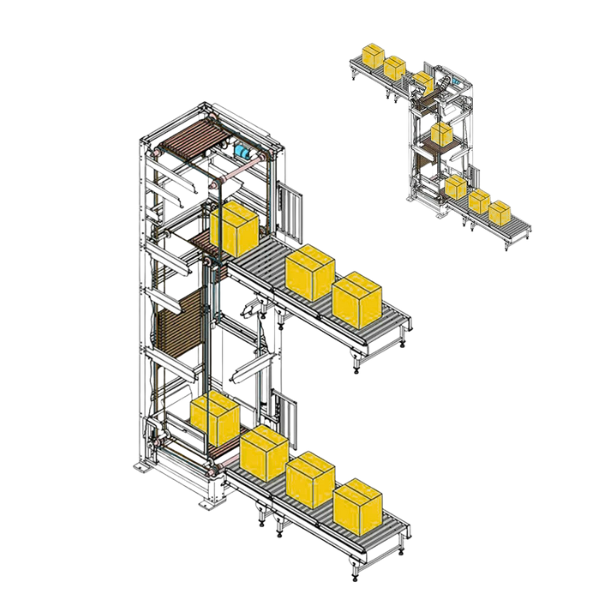

Efficient, Low-Consumption Operation & Maintenance, Strong Cost Controllability: Sorting efficiency reaches 4,500-7,200 pieces/hour, 40% higher than traditional equipment; operating noise is ≤75dB, and energy consumption is 28% lower than cross-belt sorters. Modular design with independent drive units allows faulty module replacement within 10 minutes, reducing the average fault repair time to 8 hours, with overall machine availability ≥99.5%.

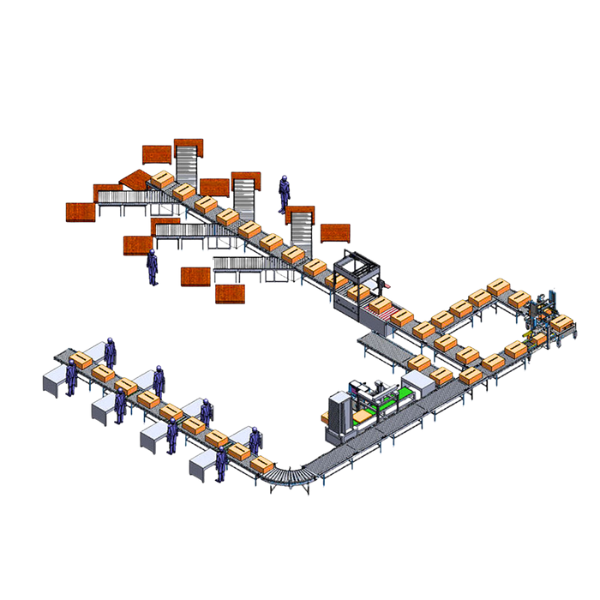

Intelligent Integration & Flexibility, Wide Deployment Scenarios: Supports RS485/Ethernet interface, seamlessly connecting to WMS/WCS systems to realize dynamic path planning, real-time data synchronization, and fault early warning. Standardized modules can be quickly spliced and expanded, with adjustable tripod height, adapting to various sites over 300㎡; renovation and upgrading can be completed within 48 hours, reducing secondary deployment costs by 70%.

Extreme Environment Adaptation, Stable Operation Globally: Low-temperature motor + constant temperature control system enables 72-hour continuous trouble-free operation at -20℃ to 45℃, and stable operation in high humidity environments with 90% humidity. Optional anti-static and moisture-proof designs meet the needs of special industries such as cold chain, military industry, and fresh food.

Product Description

The balance wheel sorter (also known as swing wheel sorter) is an automated logistics equipment integrating flexible sorting, heavy-duty adaptation, and intelligent control, specially designed to solve the pain points of traditional equipment. Its core consists of independent balance wheel modules, dual servo drive systems, and laser vision calibration units. Polyurethane-coated balance wheels combined with pressure sensing and AI contour recognition technology can safely handle 0.1-80kg multi-form goods with a sorting accuracy of 99.95%. The equipment supports stepless angle adjustment from 0-90° and multiple feeding modes, is compatible with WMS/WCS systems, adopts universal voltage design, and features a modular structure for quick deployment and maintenance. With an ROI period of only 14 months, it is a cost-effective choice for logistics automation upgrading in multiple industries.

Relevant Attributes

| Parameter Category | Specific Parameters |

| Sorting Efficiency | 4,500-7,200 pieces/hour (based on goods with average size of 400mm) |

| Conveying Speed | 30-150m/min, multi-speed adjustable |

| Applicable Goods Range | Weight: 0.1-80kg; Size: 90×90×10mm - 1500×1000×1000mm |

| Sorting Accuracy | Recognition accuracy ≥99.95%, mis-sorting rate ≤0.02%, balance wheel offset <0.5mm |

| Operating Environment | Temperature: -20℃~45℃; Humidity: ≤90%RH; Noise ≤75dB |

| Power Supply Requirement | 220V/380V AC, 50/60Hz (optional, customizable) |

| Core Configuration | PLC: Siemens/Delta; Servo Motor: Delta/Hechuan; Balance Wheel Material: Polyurethane Coating + Aviation Aluminum |

| Sorting Angle | 0-90° stepless adjustable, supporting single and double-sided sorting |

| System Connection | Supports RS485/Ethernet interface, compatible with WMS/WCS/TMS systems |

Application Scenarios

1. Home Appliance Warehousing & Logistics

Suitable for sorting large home appliance packaging boxes such as refrigerators, air conditioners, and washing machines, capable of handling extra-large goods of 1.5m in length and 65kg in weight, completing steering and sorting without manual assistance. Cooperating with AGV trolleys to realize the "warehousing-sorting-outbound" closed loop, an air conditioner enterprise reduced labor costs by 65% after application, with a daily processing capacity of 4,200 pieces and sorting accuracy improved to 99.99%.

2. Auto Parts Industry

For irregular auto parts such as engine packaging boxes and long bumpers, the flexible balance wheel unit automatically adjusts the sorting angle to adapt to boxes with a width of 100-1200mm. Equipped with RFID reading function, it completes part information entry synchronously with sorting, helping automakers like Volkswagen improve inbound logistics efficiency by 60% and reduce equipment failure rate by 70%.

3. Cross-Border Cold Chain Logistics

The -20℃ low-temperature adaptability meets the sorting needs of cold chain goods such as frozen seafood and imported red wine. Food-grade coated balance wheels ensure goods safety, and pressure control technology reduces the damage rate of red wine boxes from 1.5% to 0.03%. The angle memory function automatically adapts to sorting standards of different countries, realizing seamless connection in international logistics.

4. E-Commerce Express Sorting Centers

To cope with order surges during "Black Friday" and "Double 11", it can dynamically adjust the balance wheel rhythm, maintaining a 99.9% on-time sorting rate even when the order volume surges by 300%. Moisture-proof balance wheel sets adapt to high-humidity environments, successfully solving the sorting problems of fresh packages and soft woven bags, and are widely used in sorting hubs such as Cainiao and SF Express.

5. Pharmaceutical & Precision Manufacturing

Compliant with pharmaceutical GSP standards, optional anti-static design is suitable for sorting vaccines and precision electronic components. Flexible sorting technology reduces the loss rate of precision components from 0.3% to 0.0001%, and ensures the continuous cold chain of pharmaceutical products under low-temperature conditions, meeting the compliance requirements of pharmaceutical circulation.

6. Military Industry & Special Logistics

Custom anti-static and anti-impact modules can safely sort military precision components. Strict pressure and angle control avoid component damage caused by sorting operations. The modular design facilitates the rapid establishment of temporary sorting units, adapting to the flexible scheduling needs of military logistics and ensuring precise and controllable sorting processes.