In precision work— like electronics assembly, pharmaceutical packaging, or small parts manufacturing— every element of your production line is critical. The way that materials are moved might seem like a minor detail, but in high-stakes environments, choosing the wrong conveying mechanism can cause misalignments, damage to product(s), and valuable downtime. This is why miniature roller conveyors are an important consideration. These conveyors are built differently than most— constructed for gentle and accurate handling, and designed for seamless integration into sensitive workflows. The best miniature roller conveyor for your company is the one that best fits your operational needs, design, construction, and customization. In this article, we’ll look at the most important aspects and help you guarantee that your miniature roller conveyor is a dependable system instead of a problematic one.

Understanding how work environments operate takes time and effort. While a conveyor may work well in a typical warehouse setting, in a cleanroom or a micro-assembly line, it may perform poorly or not at all. Start by looking closely at your process. What do you convey, and how big, heavy, and durable or fragile are the items? For instance, a small roller conveyor that moves tiny semiconductor parts has very different requirements than one that moves a small vial. You must also understand the surrounding environment where the conveyor will work; is it a cleanroom, a dust- and chemical-free area, or an environment that may be exposed to oils or chemicals? What the throughput speed should be, and whether there is a need for accumulation and exact positioning are important factors as well. This initial analysis is not an end in itself, it is a starting point that will guide you through all relevant parameters, including the selection of the right materials and the type of drive. If you ignore this step, you run the risk of having inadequate equipment for the assigned task. This can make your engineers' lives difficult and hurt the end product.

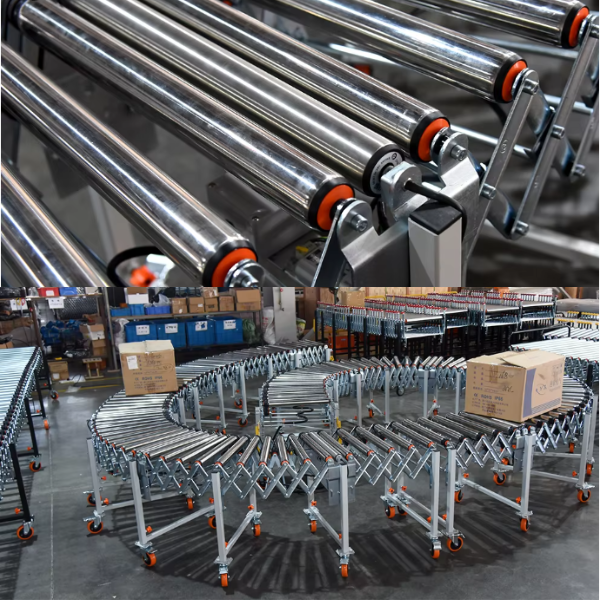

When you have complete knowledge of your application, you can review the tech specs of a mini roller conveyor and be logo engineering savvy. Roller material is very important. For most precisions jobs, stainless steel is the go-to roller material. Stainless steel has a superior corrosion resistance, is easily cleanable, and is stable dimensionally which is important for consistent performance. The frame construction is just as important as the material used for the rollers. A well constructed frame that is rigid and machined will prevent flexing of the rollers. This ensures that all rollers are aligned perfectly. The roller systems are just as critical as the frame construction. The system used should have high quality, sealed precision bearings which will have a minimal amount of friction and will also be quiet. This means that the roller will perform smoothly and won’t have maintenance issues for a long time which is important for continuous operation. The space between the rollers (pitch) is also important. It should be determined by the smallest object you expect to convey to eliminate the possibility of tipping or jamming. These details are critical for determining the type of instrument for material movement.

Standard catalog miniature roller conveyors will not fit most precise applications. This is where the importance of the custom solution from the conveyor supplier comes into play. Most suppliers should not just sell products, but rather create solutions in partnership with the customer. Try to find a supplier that offers a complete solution, which begins with a genuine dialogue about the need. They ought to have a particular interest in the details of your problem, whether it is with the logistics, manufacturing, or a laboratory. The next step of the solution is to review and produce some samples. Most credible suppliers will offer to make a sample or prototype that you will be able to test in your own conditions. This sample will help you measure the conveyor’s performance, test the clearances, and evaluate the gentle handling, all before you buy it. Professional CAD services offer custom drawing and processing which will make your final design integrate with your machinery. This will help avoid expensive surprises during the installation. These different and collaborative steps will help you see the complete picture of what the conveyors will be and will help you avoid seeing conveyors as a simple commodity.

Choosing a supplier is as critical as choosing the hardware for your systems. A company with a decade's worth of experience with industrial conveying systems has a full toolbox of what works and what doesn't. Look into your supplier's background. Do they have experience in the same industry as you, whether that's intelligent manufacturing, pharmaceuticals, or chemicals? Having experience in your industry means they've already done the homework in understanding your rules and expectations. Assess your supplier's philosophy on commitment to what they've defined as ‘durable’ and ‘reliable’ performance. Precision work conveyors are a long-term investment that should operate without issues for years. When investing in a conveyor system, consider the testing procedures and the type of warranty they offer. Having a supplier that stands confidently behind the warranty is a good peace of mind. In the end, you are not just getting a piece of equipment. You are getting a partner with your engineering team and should consider their support as a long-term extension with your team.

Roller conveyors for precision work require an understanding that is both technical and strategic and can be particularly difficult to achieve. It starts with understanding the particular needs of your application and reviewing the engineering of the conveyor from materials to bearing design. This process is made a lot easier by collaborating with a focused supplier who can provide genuine customization, sample-backed verification, and integration assistance. In precision applications, the aim is to achieve uninterrupted flow. By factoring in everything discussed, and choosing a partner with deep experience and a willingness to work collaboratively, you can make certain that your conveying system will be a dependable, high-precision connector in your production line.

Hot News

Hot News