Nedostatak radne snage u vrhunskoj sezoni, neslaganje u standardima ručnog razvrstavanja, visoki gubici zbog neidentificiranih skrivenih mana, i rastući troškovi obrade koji su smanjili profit... Te su teške točke za sortiranje ograničavale razvoj poljoprivrednih proizvoda (voća, orašastih plodova, povrća) i preduzeća za preradu hrane. Kako se tržište traži standardizacija kvalitete proizvoda, tradicionalni modeli razvrstavanja više nisu kompatibilni. Efikasno, točno i inteligentno rješenje za automatsko razvrstavanje postalo je ključ za poduzeća kako bi probila razvojne uske granice.

4 Osnovne teške točke tradicionalnih modela ocjenjivanjaDa li ih doživljavate?

Većina preduzeća za preradu oslanja se na ručni rad ili tradicionalnu jednostavnu opremu za razvrstavanje, s istaknutim glavnim bolnim točkama:

-

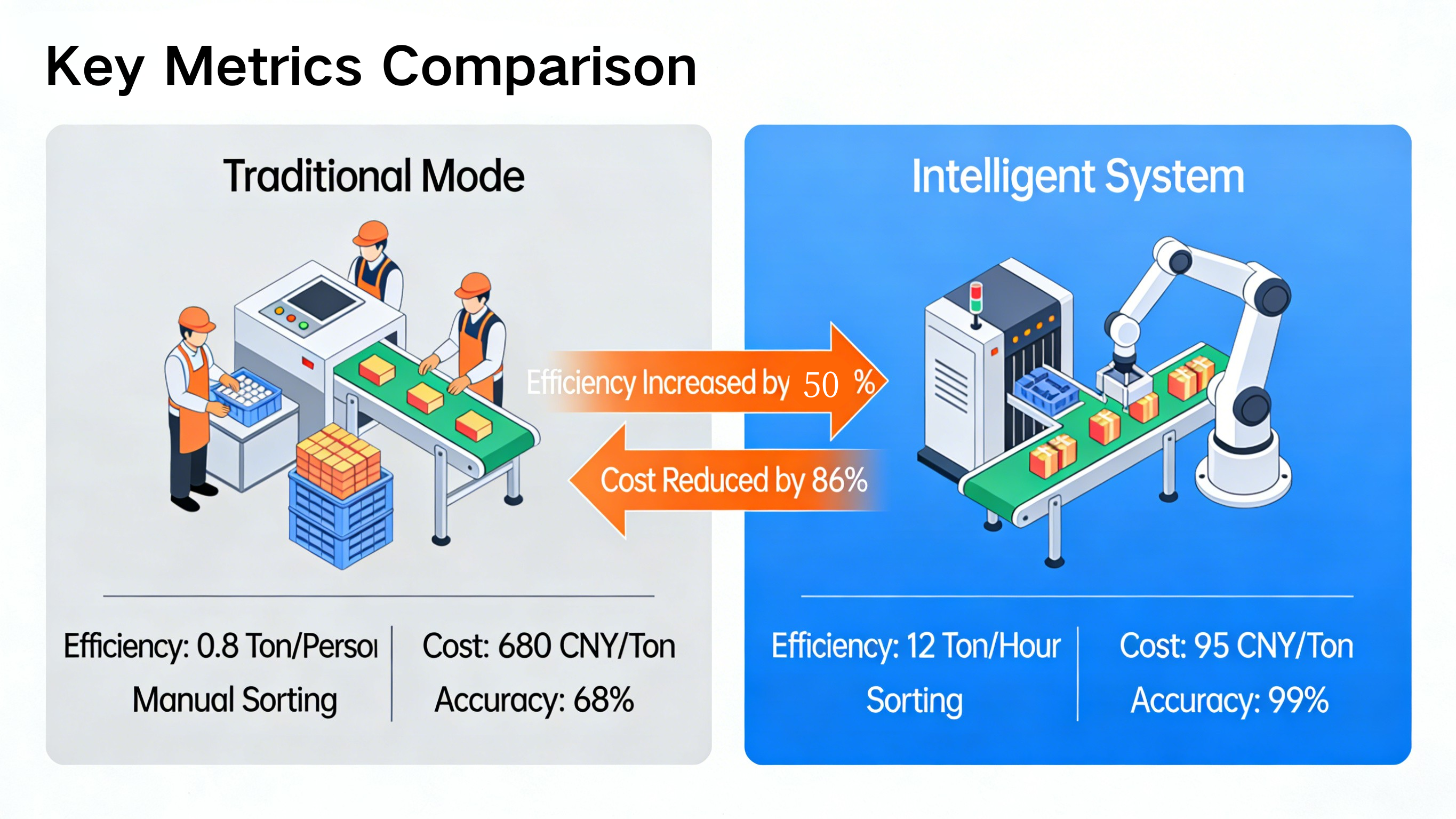

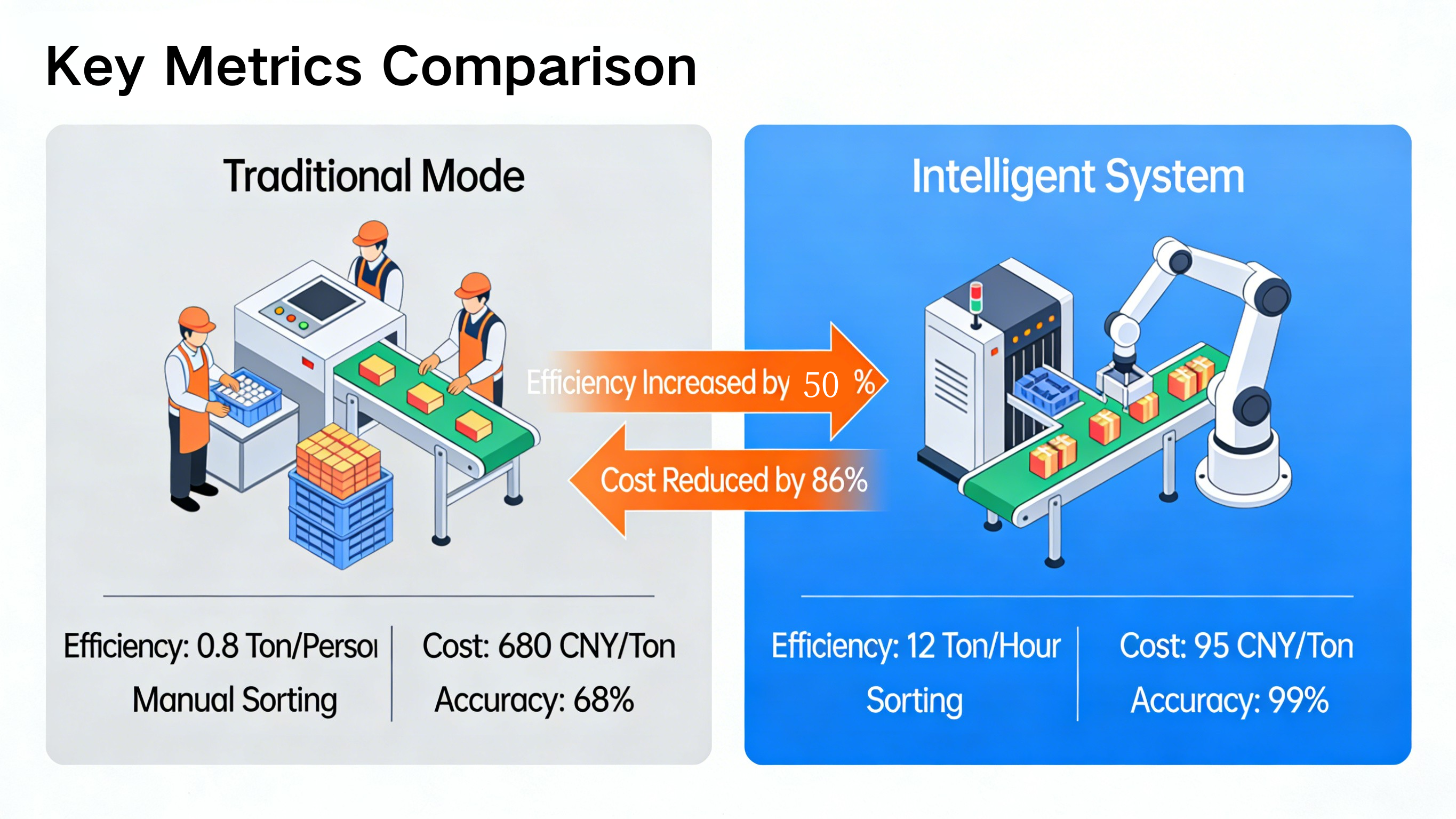

Niska učinkovitost i visoki troškovi : "Teško je zaposliti radnike" tijekom vrhunske sezone za ručno sortiranje, s dnevnoj proizvodnom kapacitetu za samo 0,5-1 tona po stanovniku; tradicionalna oprema obavlja jednodimenzionalnu razvrstavanje (npr. samo veličine), s proizvodnom kapacitetu manjom od 3 tone na sat. Troškovi rada + rad i održavanje čine više od 60% ukupnih troškova obrade.

-

Loša točnost razvrstavanja i nestabilna kvaliteta : U ručnom vizualnom prosudbi postoje subjektivne odstupanje; skriveni pokazatelji kao što su sadržaj šećera i unutarnje lezije ne mogu se identificirati, s stopom točnosti od samo 60% -70%. U skladu s člankom 3. stavkom 1. stavkom 2.

-

Visoki gubici i gubitak profita : Neidentificirani defektni proizvodi koji ulaze na tržište dovode do stope povrata od 15%-20%; defektni proizvodi također mogu kontaminirati cijele serije robe. Samo u industriji prerade voća godišnja stopa gubitka razvrstavanja premašuje 10%.

-

Nepostojanje praćenja i visoki rizici usklađenosti : U skladu s člankom 21. stavkom 1. točkom (a) Uredbe (EZ) br. 1225/2009 Komisija je odlučila o uvođenju mjera za utvrđivanje zahtjeva za zaštitu životne sredine u skladu s člankom 21. stavkom 2. točkom (a) Uredbe (EZ) br. 1225/2006.

Osnovni proboj: Inteligentni automatski sustav razvrstavanja restrukturira vrijednost veza za razvrstavanje

U usporedbi s tradicionalnim modelima, naš automatski sustav ocjenjivanja oslanja se na osnovne tehnologije kao što su AI vizualno prepoznavanje i optičko otkrivanje, ostvarujući skok od "osudbe zasnovane na iskustvu" do "odluka na temelju podataka". To stvara ključne prednosti u četiri dimenzije: učinkovitost, točnost, troškovi i usklađenost:

1. za Multiplikacija učinkovitosti: 1 sat jednako je 7 radnika 1 dan rada Nema više tjeskobe tijekom vrhunske sezone

-

Napredak u efikasnosti obrade : Jedna linija obrađuje 6-15 tona na sat (12-15 tona za plodove srednje veličine kao što su citrusi i jabuke), što je ekvivalentno 7 radnika za 1 radni dan; dvostruki kanali mogu dostići do 20 tona na sat, prilagođavajući se kapacitetu u vrhunskoj sezoni.

-

Potpuna automatizacija procesa : Od hranjenja, ispitivanja, razvrstavanja do pakiranja, cijeli proces je bez nadzora, omogućavajući neprekidnu operaciju 24 sata dnevno i potpuno rješavanje nedostatka radne snage tijekom vrhunskih sezona.

2. u. Precizna razvrstavanje: 97% točnost + višedimenzionalna potpuna inspekcija Eliminirajte skrivene nedostatke

-

Uređaj za kontrolu : Točnije identificira eksplicitne pokazatelje kao što su nedostaci u izgledu (plamenke, oči insekata itd.), veličina i težina; istodobno identificira skrivene pokazatelje kao što su sadržaj šećera i unutarnje ozljede putem nedestruktivnog ispitivanja, postižući sve

-

97% stopa točnosti : AI algoritmi obučeni na milijunima uzoraka, s stopom pogreške od <3%, daleko iznad 70% točnosti ručnog rada; podržava personalizirano modeliranje za više od 20 kategorija.

3. U redu. Smanjenje troškova i poboljšanje učinkovitosti: 80% ušteda troškova + 10% smanjenje gubitaka Direktni rast dobiti

-

Značajno smanjenje troškova : Zamjenjuje ručni rad kako bi se smanjili troškovi rada za više od 40%; troškovi sveobuhvatne obrade padaju s 600-800 juana / tone na manje od 100 juana / tone, štedeći više od 80%.

-

Značajno smanjenje gubitaka : U tom slučaju, Komisija je zaključila da je u skladu s člankom 2. stavkom 3. točkom (a) osnovne uredbe, u skladu s člankom 2. stavkom 3. točkom (b) osnovne uredbe, u iznosu od 0,5% u odnosu na prodajni kapacitet u Uniji, udio u izvozu iz Unije u Uniju bio veći od

4. U redu. Svrha i sljedivost: potpuna evidentiranje podataka Prilagođavanje zahtjevima nadzora kvalitete

-

Potpuna praćivost kroz cijeli proces : U slučaju da se u skladu s člankom 5. stavkom 1. točkom (b) i (c) ovog Priloga utvrdi da je u skladu s člankom 5. stavkom 1. točkom (b) ovog Priloga, u skladu s člankom 5. stavkom 1. točkom (c) ovog Priloga, u skladu s člankom 5. stavkom 1. točkom (b

-

Odlučivanje temeljeno na podacima : Analiza podataka iz pozadine pruža osnovu za optimizaciju kapaciteta i poboljšanje kvalitete, olakšavajući precizne operacije.

Odmah poduzmite akciju: otključajte novo rješenje za smanjenje troškova i poboljšanje učinkovitosti u ocjenjivanju

Tradicionalni modeli ocjenjivanja postali su prepreka razvoju. U skladu s člankom 3. stavkom 1. točkom (a) Uredbe (EU) br.

Kontaktirajte naše stručnjake za rješenja: obavještaj o kategoriji proizvoda i zahtjevima za kapacitet, i dobij besplatno prilagođeno rješenje!

Vruće vijesti

Vruće vijesti