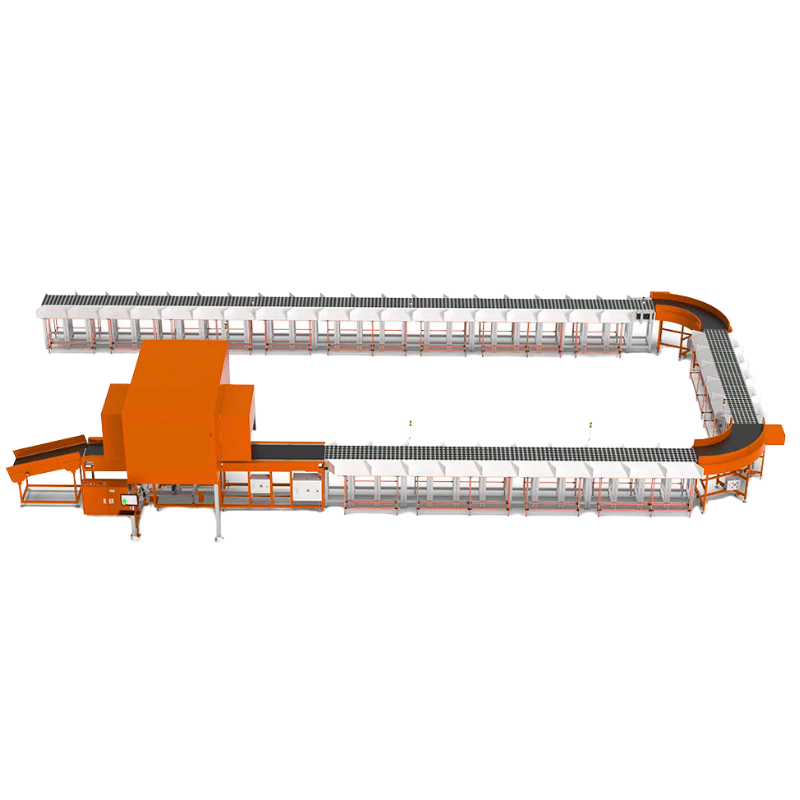

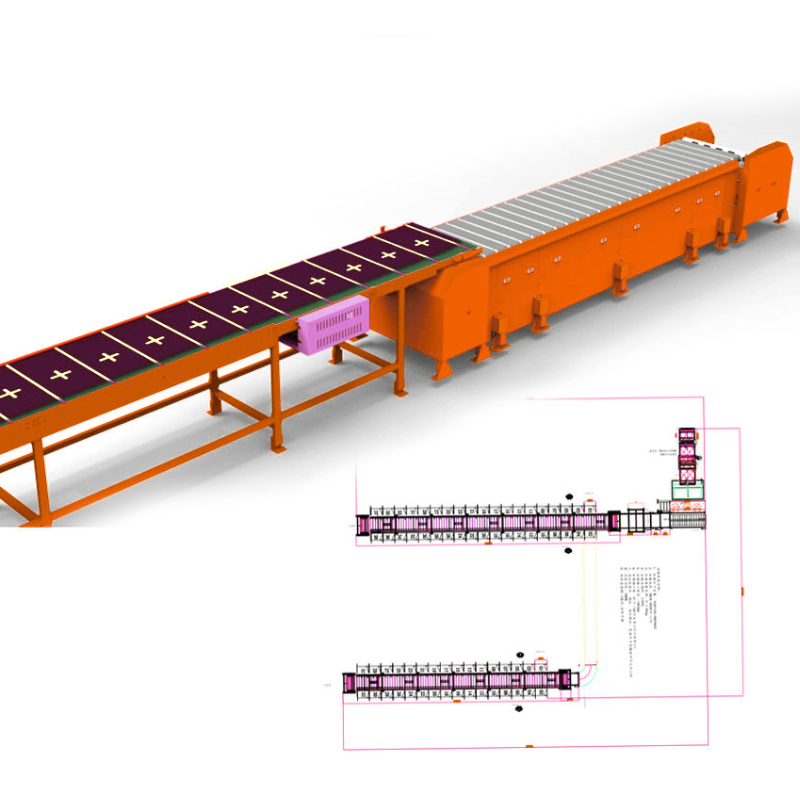

Linear Module Narrow Belt Sorter

High-Efficiency Sorting, Peak Performance

Universal Compatibility, No Fear of Irregular Shapes

Space Optimization, Low-Cost Deployment

Stable & Low-Consumption, Easy Maintenance

Flexible Operation, Damage-Free Sorting

- Overview

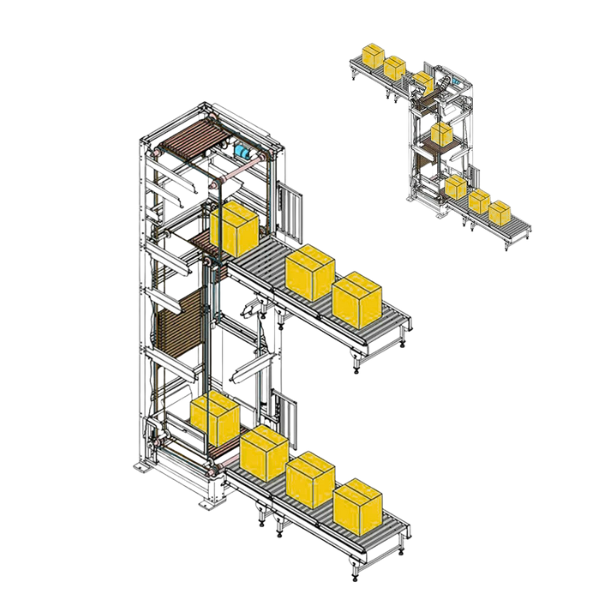

- Recommended Products

Core Product Advantages

High-Efficiency Sorting, Peak Performance: Sorting capacity reaches 8,000-18,000 pieces/hour, 3-5 times that of manual sorting. Conveying speed is adjustable from 1.02.5m/s, easily handling order surges. Equipped with a 6-sided code scanning matrix and AI vision algorithm, the barcode recognition rate is ≥99.9%, overlapping item recognition accuracy is 99.7%, and mis-sorting rate is ≤0.01%, significantly reducing rework costs.

Universal Compatibility, No Fear of Irregular Shapes: Suitable for sorting packages weighing 0.05-50kg and measuring 100×100×1mm to 1500×800×700mm, covering flat items, soft packages, irregular parts, and extra-long items (max length 2m). Narrow belt spacing is less than 30mm to prevent small items from falling, enabling one machine to handle multi-form goods.

Space Optimization, Low-Cost Deployment: Linear layout design with a minimum footprint of only 300㎡, suitable for compact spaces such as floor warehouses and small-to-medium distribution outlets. Modular structure with quick-connect interfaces eliminates the need for anchor installation, allowing commissioning and delivery to be completed in 7 days. It can be folded for storage when not in use, and secondary expansion of sorting ports can be put into use on the same day of installation.

Stable & Low-Consumption, Easy Maintenance: Energy consumption is 40% lower than traditional cross-belt sorters, with operating noise ≤75dB, meeting industrial environmental requirements. Independent modular design ensures that single-module failure does not affect overall operation; module replacement can be completed in 10-15 minutes, and the overall machine availability is ≥99.5%.

Flexible Operation, Damage-Free Sorting: Vacuum adsorption + electric roller coordination technology completes overlapping item separation in 0.1 seconds with a spacing error ≤2mm. Laser centering adaptive adjustment enables gentle sorting actions, suitable for goods requiring low impact such as fresh produce and fragile items, avoiding transportation damage.

Product Details

The linear module narrow belt sorter is a high-efficiency flexible automatic sorting equipment, specially designed to solve the core pain points in logistics sorting: low efficiency, high mis-sorting rate, large space occupation, and high labor costs. Through the "overlap separation & all-sided scanning" intelligent technology system and modular structure, it reconstructs sorting logic and realizes full-process automation from feeding, scanning, sorting to binning.

The core of the equipment consists of narrow belt trolleys, drive system, code scanning recognition system, laser centering device, and electronic control system. Multiple parallel narrow belts realize independent or linked operation through gear transmission. Cooperating with a 6-sided code scanning matrix composed of 12 high-speed industrial cameras, it can penetrate transparent packaging and aluminum foil packaging to identify 1D codes, 2D codes, and RFID tags, with a false scanning rate of less than 0.03%. For scenarios that are difficult for traditional equipment to handle, such as overlapping and irregular items, AI vision algorithm quickly identifies overlapping barcodes, laser sensors real-time calibrate the position of goods, and adaptively adjust the width of narrow belts to ensure accurate and stable sorting.

Feeding methods support three modes: manual feeding, feeding table feeding, and fully automatic feeding. It can be directly connected to the customer's WMS/MFC system to realize real-time data synchronization, order tracking, fault early warning, and automatic report generation without manual monitoring. The equipment uses 220V universal voltage power supply, plug-and-play, compatible with the power needs of most industrial scenarios worldwide. It also has low-temperature adaptability (0°C~45°C), meeting multi-environment operations such as cold chain and normal temperature.

Compared with traditional circular sorters and manual sorting, this equipment not only achieves leapfrog improvements in efficiency and accuracy but also reduces initial investment and later operation and maintenance costs through space optimization and low-consumption design, helping enterprises quickly achieve return on investment (ROI payback period can be shortened to 3 months). It is a core equipment for modern logistics automation upgrading.

Relevant Attributes

| Parameter Category | Specific Parameters |

| Sorting Efficiency | 8,000-18,000 pieces/hour (adjustable according to the number of feeding stations) |

| Conveying Speed | 1.0-2.5m/s, stepless adjustment |

| Applicable Goods Range | Weight: 0.05-50kg; Size: 100×100×1mm - 1500×800×700mm |

| Recognition Accuracy | Barcode recognition rate ≥99.9%, overlapping item recognition accuracy 99.7%, mis-sorting rate ≤0.01% |

| Operating Environment | Temperature: 0°C~45°C; Noise ≤75dB |

| Power Supply Requirement | 220V AC, 50/60Hz (universal voltage, customizable) |

| Equipment Size | Minimum floor area 300㎡, height adaptable to 850mm-8m floor height |

| Module Maintenance | Module replacement time 10-15 minutes, overall machine availability ≥99.5% |

| Control System | Supports WMS/MFC system connection, real-time data synchronization, fault early warning, automatic reporting |

Application Scenarios

1. E-Commerce Logistics Warehouses

Suitable for mixed sorting of small and medium items such as clothing, books, 3C accessories, and daily necessities, especially for order surges during "Double 11" and "Black Friday". It can realize mixed-code sorting and rapid diversion to multiple destinations, greatly shortening outbound time. Cases show that after introducing it into a medium-sized e-commerce warehouse, the sorting time for 120,000 orders was reduced from 48 hours to 8 hours, shipping efficiency increased by 83%, and labor costs decreased by 70%.

2. Express Sorting Centers

For scenarios with complex package types (cartons, envelopes, soft packages, irregular items) such as postal and cross-border express, it can realize full-process automation of inbound rough sorting, outbound fine sorting, and outlet diversion. The 6-sided code scanning technology can penetrate various packages, and the laser centering function ensures accurate binning of irregular items with almost zero mis-sorting rate. It is applicable to large sorting centers such as SF Express and Cainiao, as well as small-to-medium express outlets.

3. Fresh Cold Chain Industry

Gentle and impact-free sorting actions, combined with temperature-controlled bins, realize damage-free sorting of fresh-keeping packages such as fruits, vegetables, seafood, and frozen food. Low-temperature adaptability can cope with the operating environment of cold chain warehouses, avoiding the impact of temperature fluctuations on goods quality during manual sorting, while improving sorting efficiency and reducing cold chain energy consumption.

4. Pharmaceutical Distribution Field

Compliant with GSP standards for pharmaceuticals, it can penetrate aluminum foil packaging to read electronic supervision codes, realizing accurate sorting and traceability of drugs and medical devices. High recognition accuracy and low mis-sorting rate ensure compliance in pharmaceutical circulation, avoiding the risk of drug mixing and misdelivery. It is widely used in pharmaceutical enterprise warehouses and medical distribution centers.

5. Manufacturing Post-Process Logistics

Suitable for sorting needs in production links such as auto parts, daily chemical packaging, and electronic products. It can automatically divert parts to corresponding process positions according to their size, shape, and weight, connecting production lines and warehousing links. The independent modular design can be flexibly integrated into existing production lines without large-scale transformation, helping manufacturing enterprises achieve an automated closed loop.

6. Supermarket Distribution Centers

For the mixed sorting needs of multiple categories such as supermarket snacks, daily necessities, and fresh produce, it can quickly split and assemble multi-store orders, support small-batch and high-frequency sorting, shorten the distribution cycle, improve store replenishment efficiency, and reduce out-of-stock and misdelivery problems caused by manual sorting errors.