Beverage Filling Production Line with Dust Cover, Capping, Screwing & Labeling Functions

High precision and stability

High productivity

Good adaptability

Health and safety

- Overview

- Recommended Products

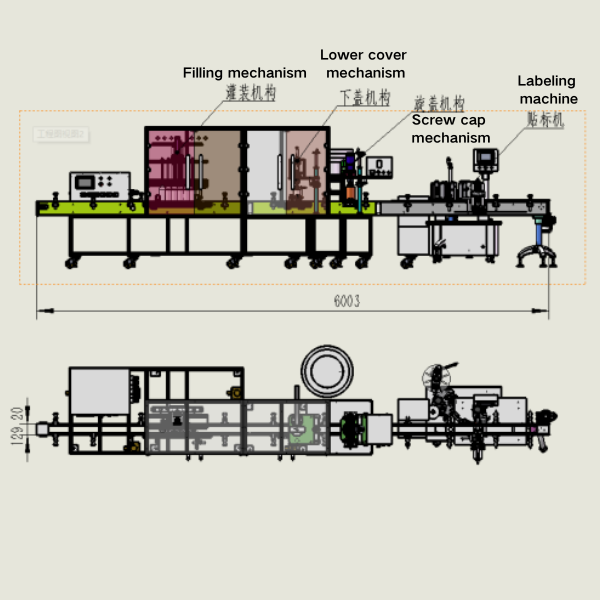

Composition & Workflow

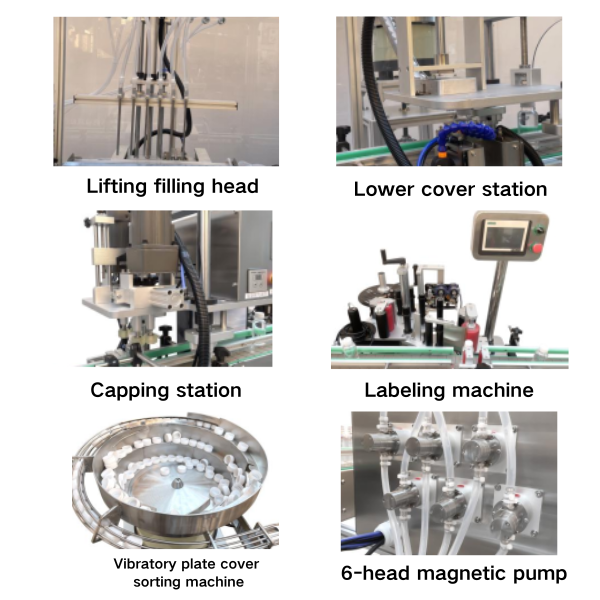

1、Filling Process: Bottles arrive at the station accurately; common fillers (gravity, piston, negative pressure) are used. Gravity type (for high-flow drinks like purified water) fixes bottles, lowers filling heads, lets drinks flow by gravity, and controls volume via level sensors/time for consistent, low-error filling.

2、Dust Cover Function: Installed above key stations, forming a semi-enclosed space. Blocks dust/foreign matter to avoid contamination, reduces spray/dust diffusion, maintains workshop cleanliness, and meets food/beverage hygiene standards.

Capping Preparation: Filled bottles move to the station. A vibratory bowl arranges caps uniformly, which are picked by suction cups/claws and placed on bottle mouths. Sensors monitor for accurate capping.

3、Screwing & Sealing: Bottles proceed to the station. The capping machine rotates heads (motor-driven) with adjustable torque (per cap specs) for tight, leak-proof sealing without damage.

4、Labeling Process: Labeling machine at the end handles various labels (adhesive, shrink sleeve). Bottles rotate at constant speed; labels are precisely attached. Photoelectric sensors ensure straight, bubble-free labeling.

Relevant Parameters

| Filling Error | ±1% |

| Number of Filling Heads | 6 heads (customizable) |

| Filling Speed | 1000-1500 bottles/hour |

| Filling Range | 100-500ML |

| Capping Range | 20-60MM |

| Maximum Suction Lift | 2 meters |

| Power Supply | 220V/50HZ |

| Applicable Air Source | 0.4-0.6MPA |

| Equipment Material | Combination of 201 stainless steel and aluminum |

| Equipment Power | 1000W |

Applicable Scenarios

1. Bottled Water Production: The production line rapidly and accurately completes filling, capping and labeling, ensuring product tightness (leak-proof), meeting the demand for large-scale, high-quality bottled water production.

2. Fruit Juice Beverage Manufacturing: For pulp-containing fruit juices, the filler adopts special technology to ensure uniform filling. Capping and labeling highlight product features, enhancing market competitiveness.