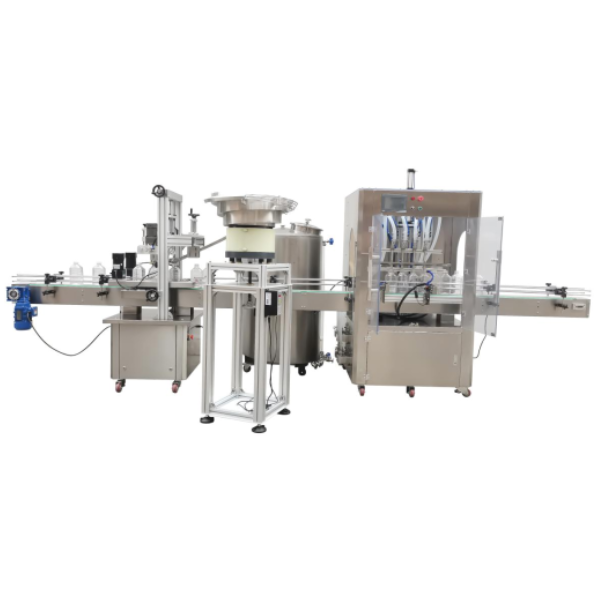

Beverage filling with dust cover Top cap capping line

1、High precision and stability

2、High productivity

3、Good adaptability

4、Health and safety

- Overview

- Recommended Products

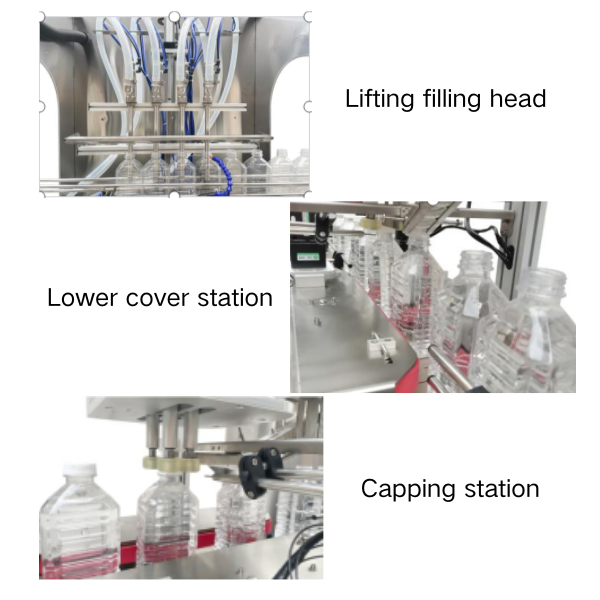

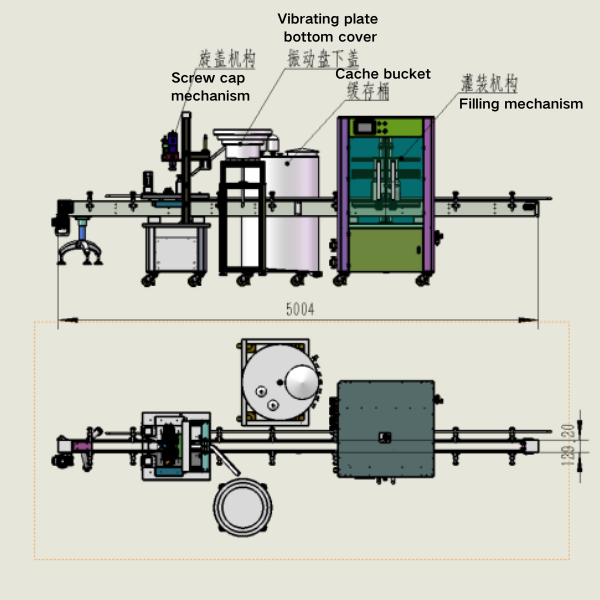

Composition & Workflow of Production Line

1、Filling Process: Bottles are manually placed on the conveyor to the filling station. Filling methods (gravity, piston, negative pressure, etc.) vary by product. For gravity filling (high-flow liquids): bottles are positioned, filling heads descend, liquid flows by gravity, and volume is controlled via time/level sensors for consistency.

2、Capping Preparation: Filled bottles move to the capping station. A vibratory bowl arranges caps, which are picked (by suction cup/claw) and placed on bottle mouths. Sensors ensure accurate capping.

3、Screwing & Sealing: Bottles go to the screwing station. The capping machine rotates capping heads with adjustable torque (per cap specs) for tight sealing without damage.

4、Dust Cover Function: Installed above key stations, it isolates work areas, prevents contamination from dust/foreign matter, reduces spray/dust diffusion, and meets hygiene standards.

Relevant Parameters

| Filling Error | ±1% |

| Number of Filling Heads | 4 (Customizable) |

| Filling Speed | 1000-1500 bottles/hour |

| Filling Range | 100-1000ML |

| Capping Range | 20-60MM |

| Maximum Suction Lift | 2 meters |

| Power Supply | 220V/50HZ |

| Air Supply Requirement | 0.4-0.6MPA |

| Equipment Material | 304 stainless steel and aluminum alloy combination |

| Equipment Power | 1000W |

Applicable Scenarios

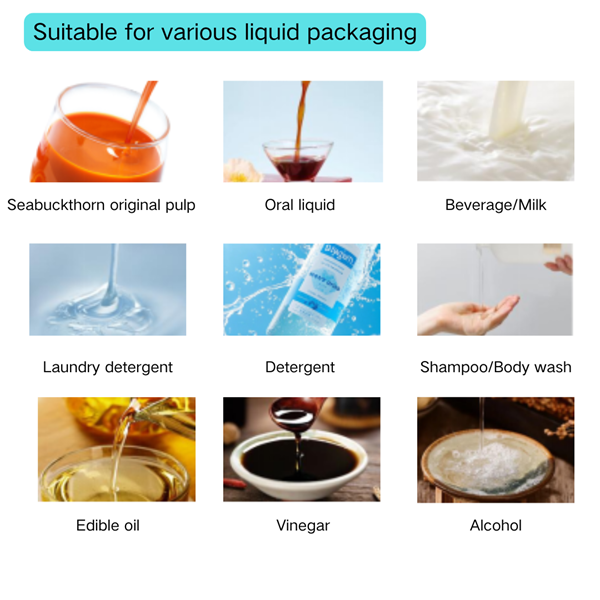

Food & Beverage Industry: Suitable for packaging bottled water, fruit juice, soy sauce, vinegar, etc. Enables fast and precise filling & capping, ensuring tight sealing and leak-proof performance to meet large-scale, high-quality production needs.

Daily Chemical Industry: Applicable to shampoos, body washes, skin care products, etc. Dust-proof design + accurate capping effectively guarantees product hygiene and sealing, enhancing market competitiveness.

Pharmaceutical Industry: Ideal for small-dose drug packaging (oral liquids, eye drops, etc.). High-precision filling, hygiene protection, and stable capping meet strict pharmaceutical production standards, ensuring product quality and safety.